Air treatment, an essential aspect of the agri-food industry

The food industry is particularly demanding a sector as far as air conditioning is concerned. Each parameter (temperature, humidity, microbial air quality) needs to be perfectly controlled in order to ensure optimum quality for the agri-food products and prevent health hazards. Air treatment plays a key role in the processes of the agri-food industry. ETT HVAC solutions specifically address these requirements.

ETT Solutions

Specific air treatment systems for the agri-food industry

ETT creates and markets different types of units that meet the concerns of the first food industry, that comprises bakery, fishery, butchery, as well as chocolate and biscuit factories… Our solutions meet the technical requirements inherent to each of our clients’ applications.

ACUs for agri-food premises have to meet 4 main requirements:

- Ensuring employee comfort

- Producing and preserving quality products

- Guaranteeing smooth operation

- Increasing productivity

This means controlling 3 parameters:

- Temperature: cooling or heating

- Humidity: humidification or dehumidification

- Air quality: ventilation, filtration, extraction

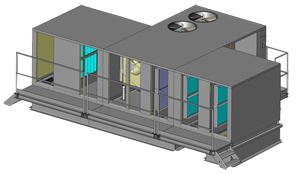

ETT creates, manufactures, commissions and maintains thermodynamic air conditioners. Those units can operate as reversible heat pumps or in Cooling mode only, with outside air or water circulation (geothermal or water loop) as an exchange source. Our units directly treat the inside air in order to limit the losses due to thermal exchanges. They can also use a heat-transfer fluid. The "Free Cooling" mode has been developed in order to optimise cooling and the "Free Heating" mode to optimise heating using outside air. External recovery systems have also been added to avoid using thermodynamic circuits. Our air conditioning units offer a broad range of possibilities:

- High flow rates, up to 80,000 m3/h

- Cooling and heating capacity up to 600 kW

- Additional heat sources (hot water, electricity, gas)

- Dedicated control systems for each application

- Specific filtration systems (HEPA, HUPA, electrostatic, activated carbon)

- Operation in extreme outside conditions

- Humidification or dehumidification systems

- Hybrid combinations (solar energy, gas and/or water loop, geothermal energy)

- Delivery in several blocks

- Special insulation

- Adiabatic systems

- Low-noise operation

- Customisable dimensions

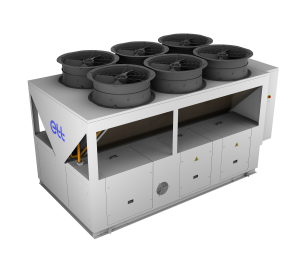

Recommended ETT units

NEROMAX: High-temperature air-to-water heat pump

Bespoke units for the Agri-food industry:

ETT designs units that specifically meet the constraints of Retail applications.

For more information, contact your Sales Manager

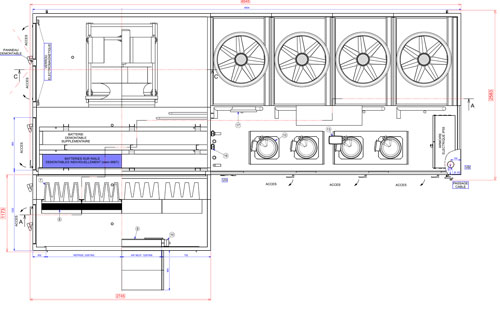

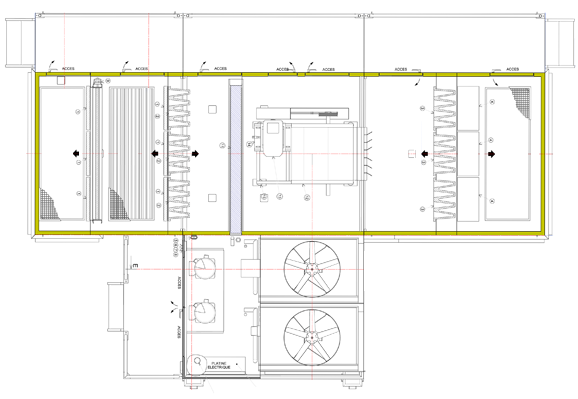

Example applications in an industrial bakery

1 – To meet a specific dust constraint, ETT air treatment system provides an adequate filtration solution

- Filtration on return air to limit the amount of dust (flour) when mixed to fresh air, especially if the humidity level is high.

- Gateway around the unit

2 – To meet a dehumidification constraint, we have designed an appropriate solution:

- Plug fan motor

- Skid-mounted batteries

- In-line condenser for thermodynamic dehumidification