Greater travellers’ comfort and lower energy bills

ETT designs and markets different types of machines adapted to the needs of the airport and aeronautical sectors, aircraft manufacturers, MRO …

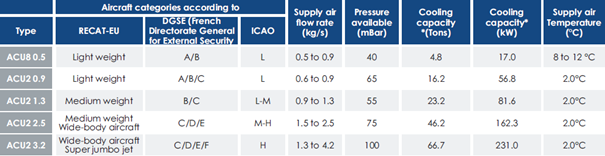

The air preconditioning units are designed to replace the APU. Our ACUs have been developed according to aircraft types and LPGC connector requirements, to provide the air flow and pressure needed for cooling and heating in APU OFF operation.

ETT’s French manufacturing quality ensures the reliability and durability of its machine.

If you are an airport operator, an Engineering and Design office specialising in aeronautics or an aircraft manufacturer, you are undoubtedly faced with one of these problems:

- Reduce CO2emissions with an APU OFF operation.

- Save energy: The thermodynamic system is an efficient, economical and environmentally-friendly solution for cooling aircraft.

It offers optimum performance with low energy consumption. - Modularity and adaptability: Mobility being a key element of the aeronautical market, the ETT units can be easily installed on:

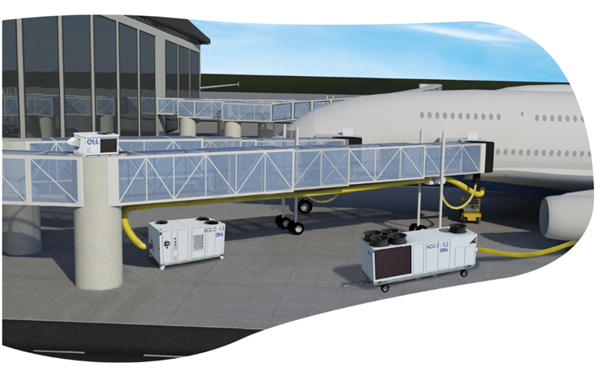

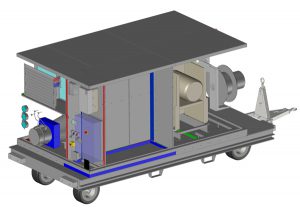

Mobile versions of the machines, which can be easily moved close to the aircrafts (ACU – towable mobile version).

Our flexible approach allows for customised air conditioning solutions that can be combined as needed:

|

| ACU/PCA |

- ACU units are stationary on the ramp and are available in towable mobile version.

The combination of a lightweight construction in aluminium that can be recycled and the use of high-efficiency, energy-saving components is part of a demanding economic context that favours overall cost.

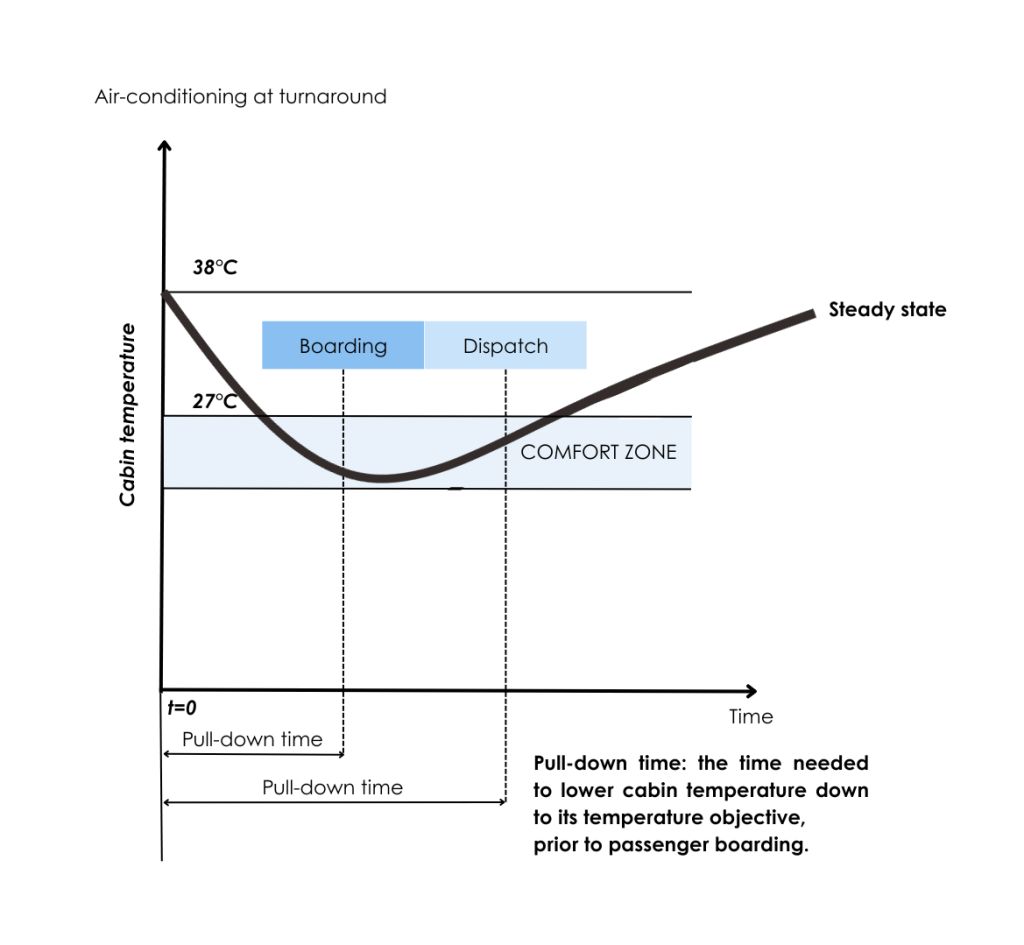

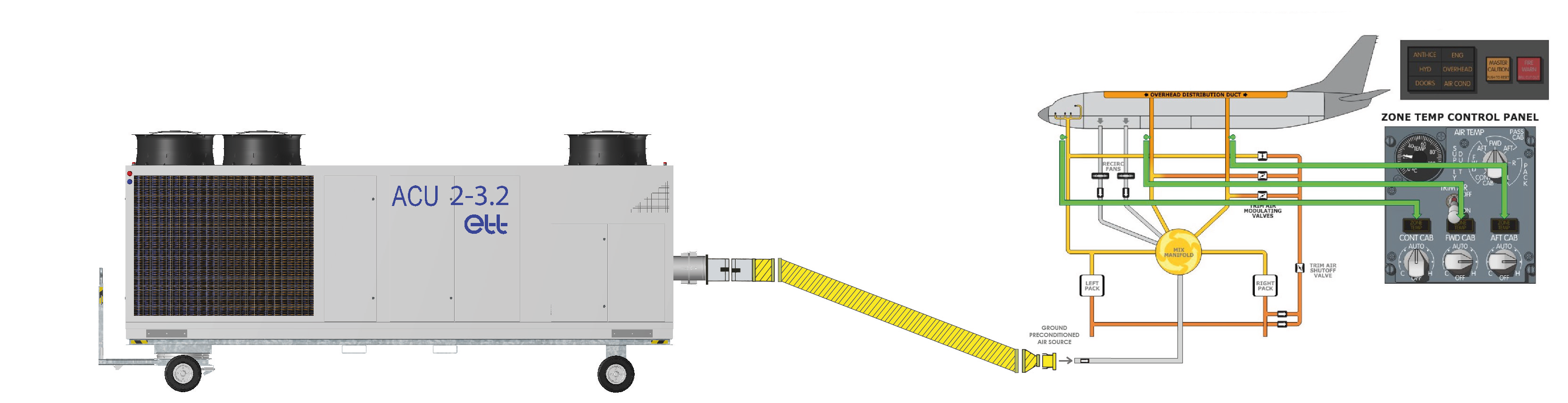

ACU units operation principle

ACU/ PCA units operation principle

ACU/PCA allows you to maintain user comfort while reducing your energy bill and your carbon footprint.

ETT designs and markets different types of machines adapted to the needs of the airport sector.

ACUs (Aircraft Air Conditioning Units) are specially designed to ensure optimum comfort for aircraft users by cooling, heating or ventilating the aircraft when it is on the ground.

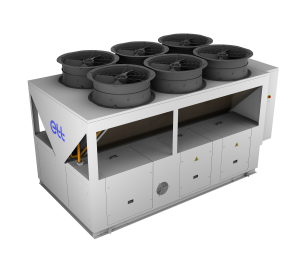

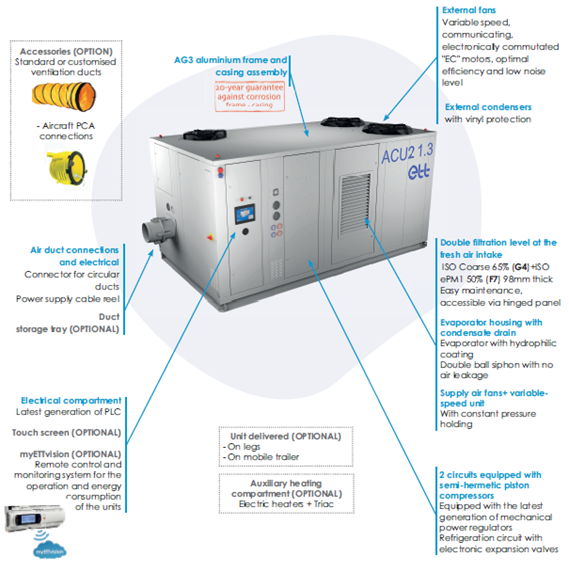

Each refrigerant circuit features an autonomous propeller fan to ventilate its heat exchanger. The propeller fan consists of a ferrule, a high-energy performance aluminium propeller, and a galvanised steel protective grill, with cataphoresis protection and epoxy coating, all of which are perfectly weatherproof. This new fan design increases the airflow through the heat exchangers by 13% compared with a conventional solution, while maintaining the same power consumption.

We offer solutions to the technical constraints inherent in each of our customers’ applications.

Contact the ETT airport market manager to discuss your requirements and specific needs.

Air treatment units for aeronautics – Operating principle

The solution with APU OFF

| CO | Carbon monoxide |

| NMVOC | Non-methane Volatile Organic Compounds |

| NOx | Nitrogen oxides |

| PM10 | Particles with a diameter of less than 10 microns |

| Type of aircraft | Short/Medium-haul aircraft | Long-haul aircraft |

| APU service life | 45 min. | 75 min. |

| Fuel consumption | 80 kg | 300 kg |

| CO2 emissions | 252 kg | 945 kg |

| Nox emissions | 700 g | 2400 g |

| CO2 emissions | 30 kg | 160 g |

| CO2 emissions | 310 g | 210 g |

| CO2 emissions | 25 g | 40 g |

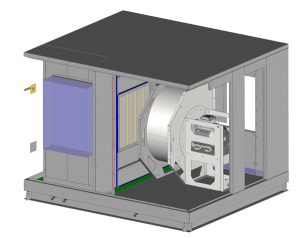

The unit operates as an air conditioner

- Source: outside air

- Treated fluid: air

The ACU/ APU offers several operating modes:

- Energy saving system: cooling with outside air without thermodynamics

- Heating using an electric auxiliary (optional)

- Air conditioning

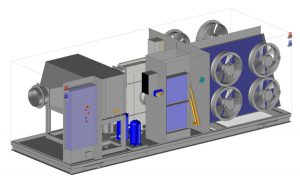

The ETT packaged unit consists of 3 separate compartments:

- An internal compartment for air handling by air blowing (optional: heating with electric heater).

- The external section allows heat dissipation in air conditioning mode.

The separate technical section houses the refrigeration components, the electrical board and the control components.

The Air Handling Units for aeronautics are designed as aluminium packaged units with watertight floor, comprising:

- an aluminium watertight frame with condensate drain pans and drainage outlets around the unit

- AG3 aluminium roof and vertical panels with acoustic and thermal insulation

- an independently insulated air stream.

Rigid, compact and lightweight packaged unit, perfectly weather-resistant, with a 20-year anti corrosion guarantee on casing. Stainless steel hinged doors, gasket under compression for perfect tight sealing.

Recommended ETT units - Aeronautics

ACU: Mobile air conditioning unit

Outdoor installation, fixed or trailer-mounted

ACU085 sur le NH90

Outdoor installation (fixed or trailer-mounted)

ACU2-1.3

Outdoor installation (fixed or trailer-mounted)

ACU2-2.5

Outdoor installation (fixed or trailer-mounted)

ACU2-3.2

Outdoor installation (fixed or trailer-mounted)

TEST BENCH: Test unit for aircraft under construction

Outdoor installation (fixed or trailer-mounted)

Bespoke units for the aeronautic sector

ETT designs bespoke products that are perfectly adapted to airport applications and your constraints.

Recommended ETT units - Airports

NEROMAX: High-temperature air-to-water heat pump

ULTI+ R32: Single flow unit with plug fan – EUROVENT certified

Available for Cooling only (optional)

PCA: Ventilation solution for stopover aircrafts

Outdoor installation, under boarding bridge

EXTRACTOR: ATEX, for polluted air removal in explosive atmospheres

Bespoke units for the Airport sector:

ETT designs units that specifically meet the constraints of Airport applications.