Subscrib newsletter ETT

Request commissioning

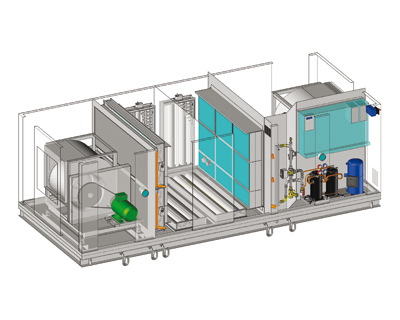

FR CH RE / HPE+ RL air treatment system is specifically designed for the ventilation, heating and air conditioning of buildings with variable occupancy, such as movie theatres, theatres and multipurpose halls. These double flow heat pumps include various equipment to use energy more efficiently.

Reversible heat pump with 20-year anti-corrosion guarantee

FR CH RR / HPE+ CEE heat pump offers fully optimised air treatment.

Thanks to its full aluminium structure (frame & casing) which ensures an excellent corrosion protection, this air conditioning and heating system is covered by a 20-year anti-corrosion guarantee.

This single flow rooftop heat pump is delivered ready to operate. A separate technical section facilitates service and control of the unit and allows measurement and adjustment during operation.

This air handling unit operates as a reversible heat pump

- Source: outside air + internal air (in recovery mode)

- Treated fluid: internal air + hygienic air

Operating modes can be:

- Heat pump

- Air conditioner

- Free cooling: cooling with outside air, without thermodynamics

In those cases, the double flow heat pump operates:

- In all recycling mode

- In all fresh air / all exhaust air

- In mixing mode

FR CH RE / HPE + RL double flow heat pump ensures air extraction and fresh air modulation while maintaining a constant indoor pressure.

The ETT packaged unit comprises 3 separate sections:

- The separate technical section houses the refrigeration components, the electrical board and the control components.

- The internal section ensures air change and air treatment.

- The exhaust air section allows exhaust air calories recovery and/or removal (depending on the operating mode).

Frame – Casing

- Motorised external damper for supply air (2006/42/EC Directive)

- Painting

- Whistle shaped cowl for fresh air on top

- Delivery in two blocks

Acoustics

- Technical section acoustic insulation using STOPFLAM flexible fire-proof polyurethane foam

- Fresh air cowl sound insulation

- Compressors acoustic jackets

Air handling

- Magnehelic dial pressure gauge at each filtration stage

- Analog air flow controller (AFC), air flow rate indication and measurement

- Filters fouling analog control (FFAC)

- Backed-up self-contained smoke detector

- Epoxy coating for fans & Vinyl coating for exchangers

- Supply air fan available pressure 600 Pa maxi

- Exhaust air fan available pressure 400 Pa maxi

- Operation in all recycling or all fresh air mode (not available for public access buildings)

- G4 refillable filters

- 1 set of spare G4 filters, 98 mm thickness

- G4 refillable filters

- 1 set of spare G4 filters, 98 mm thickness

- F6 to F9 opacimetric filters, 98 mm thickness

Thermodynamics

- HP and LP pressure gauges

- Electronic expansion valves

Thermal exchangers

- 3-stage electric heater

- Triac

- 2-row hot water coil with analog freezestat

- Vinyl coating on hot water coil

- Hot water progressive 3-way valve mounted with analog freezestat

- Mounted stop valve + TA regulating valve on exchanger outlet

Electricity

- Unit global energy metering

Control

- Banning of free cooling using specific humidity comparison

- Hygrometry probe (for external humidifier control)

Laying

- Adjustable aluminium ventilated roof curb

- Adjustable aluminium connection roof curb

- 200 or 400 mm aluminium feet

Energy Recovery

- SRF: exchanger for DHW using subcooling with a 15-28°C capacity (please consult us for performances) (except for CH 09-19 units)

- Desuperheater: additional air to refrigerant exchanger to partially dehumidify supply air