Single flow rooftop heat pump with condensing gas boiler: ULTI+ CC+

ULTIMA is ETT new modular range of rooftop units. ERP2021 ready, it combines energy efficiency and acoustic performance and includes a new generation control system that ensures unit optimal operation at all times.

The modular design of the ULTIMA range allows you to adapt unit capacity to your needs. You may choose to install the standard ULTI+ heat pump, or to customise the packaged unit with additional modules such as condensing boilers, creating an ULTI+ CC+ unit and adapting its performance to the environment and requirements of your application.

Description

The ULTI+ CC+ is covered by a 20-year guarantee against corrosion

The ULTI+ CC+ is a NEW GENERATION single flow heat pump combined with one or more condensing boilers. This unit offers optimum air quality.

For cold environments, the CC+ module is used as an auxiliary, to complement the thermodynamic system or to replace it if the outside temperature is too low. This rooftop unit combines the latest technological developments to ensure optimised energy consumption.

Thanks to its full aluminium structure (frame & casing) that ensures an excellent corrosion protection, this air conditioning system with gas heating is covered by a 20-year guarantee against corrosion.

This single flow rooftop unit with one or more condensing boilers is delivered ready to operate. The separate technical section facilitates service and control of the unit and allows measurement and adjustment during operation. This reliable and highly resistant unit is recommended for large spaces and can be installed either on a rooftop or at ground level, depending on your needs.

The unit operates as a reversible heat pump:

- Source: outside air

- Treated fluid: internal air

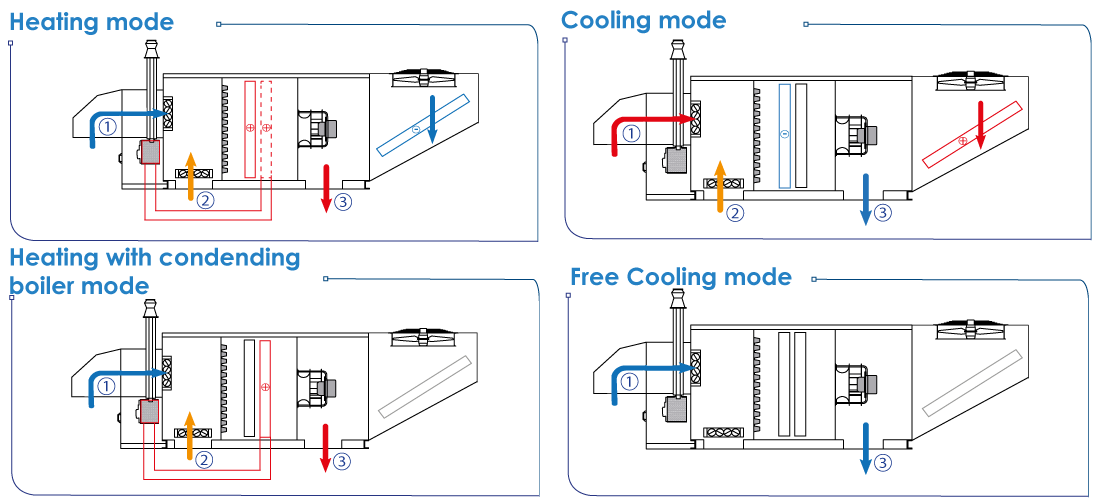

The CC+ module offers several operating modes:

- Heat pump

- Air conditioner

- Free Cooling: cooling with outside air, without thermodynamics

- Heat pump + condensing boiler

- Condensing boiler

- Heating mode: In winter, comfort temperature is maintained thanks to the thermodynamic system and auxiliary heaters (optional).

- Cooling mode: In summer, comfort temperature is maintained thanks to the thermodynamic system.

- Heating with condensing boiler mode: In winter, comfort temperature is maintained thanks to the condensing boiler system.

- Free Cooling mode: In mid-season, comfort temperature is maintained using in priority the difference between outside air and inside air to cool the building. Free Cooling allows considerable savings by delaying the use of thermodynamics.

The ETT packaged unit comprises 4 different sections:

- The external section allows thermal exchanges with the environment.

- The separate technical section houses the refrigeration components, the electrical board and the control components.

- The internal section ensures air change and air treatment.

- The separate technical section houses the condensing boiler(s) and the control components.

Available options

Frame – Casing

- Double skin, 13/10 AG in internal section, 50 mm

- Motorised external damper on supply air (2006/42/EC Directive)

Acoustics

- Low Noise EC supply air fans

- Compressors acoustic jackets

Air handling

- Operation with all recirculated air (excluding Public Buildings)

- Operation with all fresh air

- Actuating smoke detector with battery back-up

- Epoxy coating on supply air fans

- Analogue air flow controller (AFC) with supply air fans flow rate auto-adjustment

- Pressure gauges for supply air filters

- Refillable 98 mm G4 filters on supply air with analogue probe

- 98 mm M5 filters on supply air with analogue probe

- G4 + F7 double filters or F9 filters (48 + 48 mm) on supply air with analogue probe

- 98 mm F7 filters on supply air with analogue probe

- 98 mm F9 filters on supply air with analogue probe

Thermodynamics

- ETT SRV control (variable cooling system)

- Cooling only operating mode (non-reversible unit)

- Compressor MAP monitoring

- Vinyl coating on thermodynamic coils

- Refrigerant leak detection aid

- HP and LP pressure gauge

Auxiliaries

- Recovery hot water coil with analogue frost thermostat (if CC+ module connected as auxiliary)

- Auxiliary hot water coil with analogue frost thermostat (if CC+ module connected for preheating)

- Progressive 3-way valve for hot water coil

- Stop valve on outlet + TA regulating valve on inlet for hot water coil

- Auxiliary 2-sequential stage electric heaters + Load shedding using dry contact

Electricity

- Total electrical energy metering according to 2002/91/EC

- Aluminium/copper connection terminal blocks (aluminium mandatory for power cables)

- 230V/16 A single-phase socket in the technical section (separate power supply to be provided by the installer)

- Phase checker

- IT earthing system compatibility

- Cable protective cowl for outside power supply (to be mounted by the installer)

Installation

- Aluminium adjustable connection roof curb

- Aluminium adaptation connection roof curb

- Aluminium adjustable ventilated roof curb

- Aluminium ventilated adaptation roof curb

- Aluminium plenum for return air and supply air

- 200 or 400 mm aluminium feet

Control

- Operation in year-round mode (compressor authorisation in Cooling mode with outside temp. < +15°C)

- Control function in Comfort mode (setpoint temperatures control by PID)

- Free Cooling banning based on specific humidity comparison

- VDP operation (power/flow rate variation)

- HPE+ operation (High Energy Performance)

- Dehumidification function level 1 (without heating capacity recovery)

- Dehumidification function level 2 (with heating capacity recovery & on/off refrigerating 3WV)

- Dehumidification function level 3 (with heating capacity recovery & analogue refrigerating 3WV)

- Average room temperature (4 probes)

- Minimum fresh air slaving using turret contacts (2 maximum)

Gas

- Connectable gas metering (delivered dismounted – external mounting by the installer).

- Mounted 300-20 mbar gas expansion valve (different according to the types of gas)

- Condensing boilers used for preheating

- Condensing boilers used as auxiliaries

Communication

- myETTvision

- ETT TouchScreen remote touchscreen display

- Modbus RS485

- Modbus IP

- BACnet IP

- LonWorks

- Konnex