Managing air treatment in extreme environments

As a leader in air conditioning units designed for intensive use in harsh environments (including Atex zones), ETT provides specific air treatment systems based on robust and reliable equipment whose specifications meet the most demanding requirements.

ETT Solutions

The climatic answer to the Oil & Gas market requirements

ETT creates and markets different types of units that address the specific concerns of the Oil & Gas market. The cooling systems are intended for intensive use in hostile environments (tropical climate, offshore platforms, desert regions). Our strong know-how, combined with a constant watch on technological and regulatory developments allows us to offer state-of-the-art HVAC equipment that address our clients’ specific needs and constraints. ETT has implemented special processes to meet the requirements of the Oil & Gas market:

|

|

|

|

|

|

|

Recommended ETT units

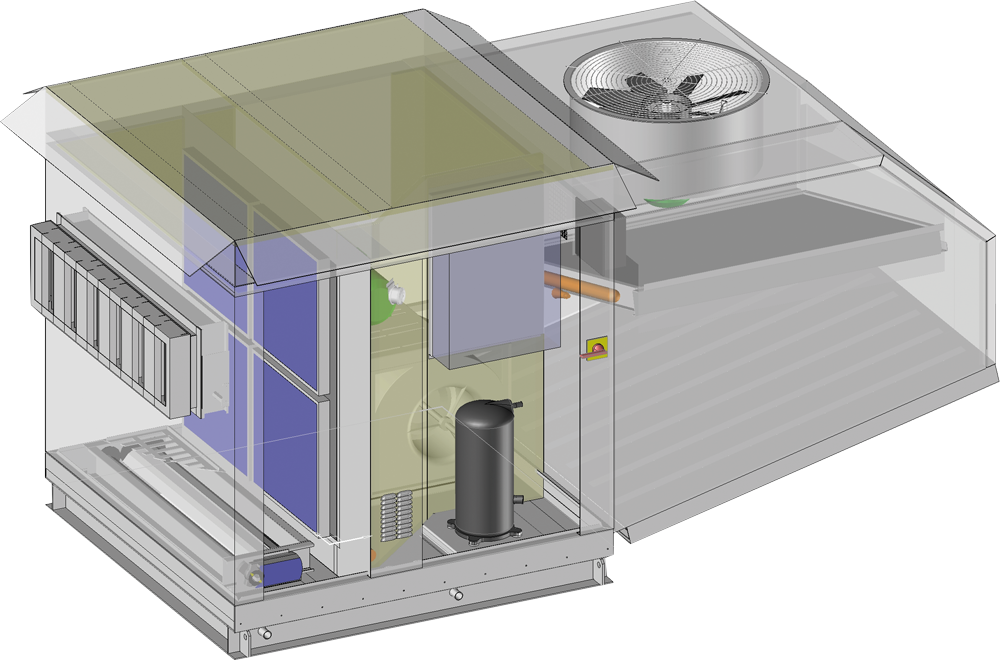

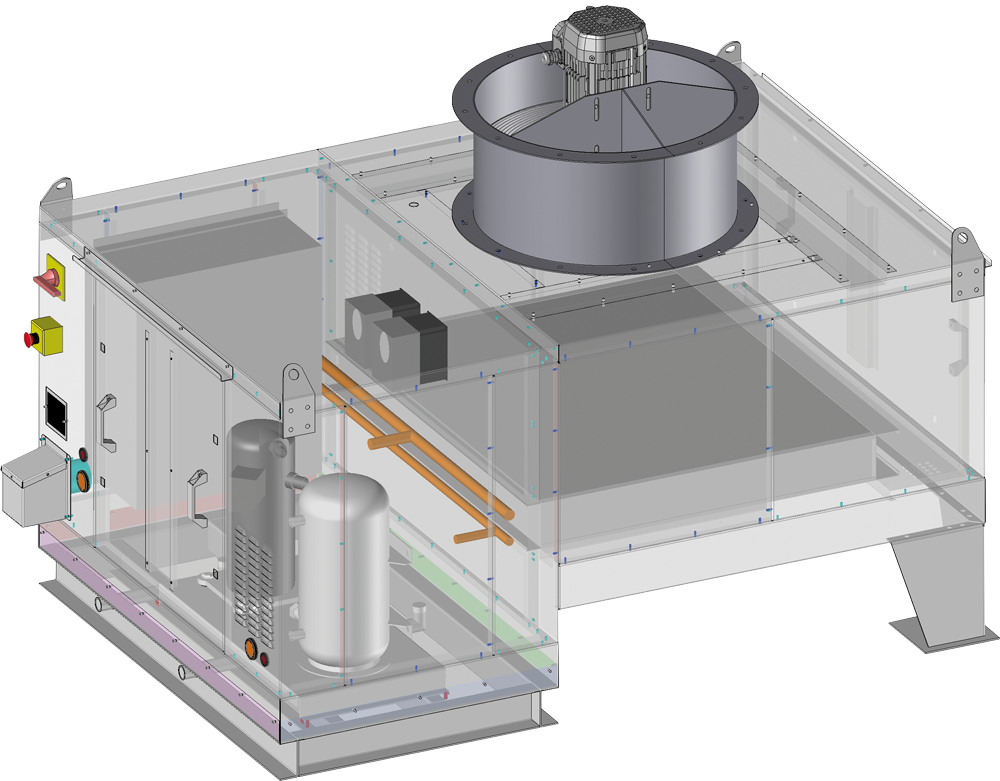

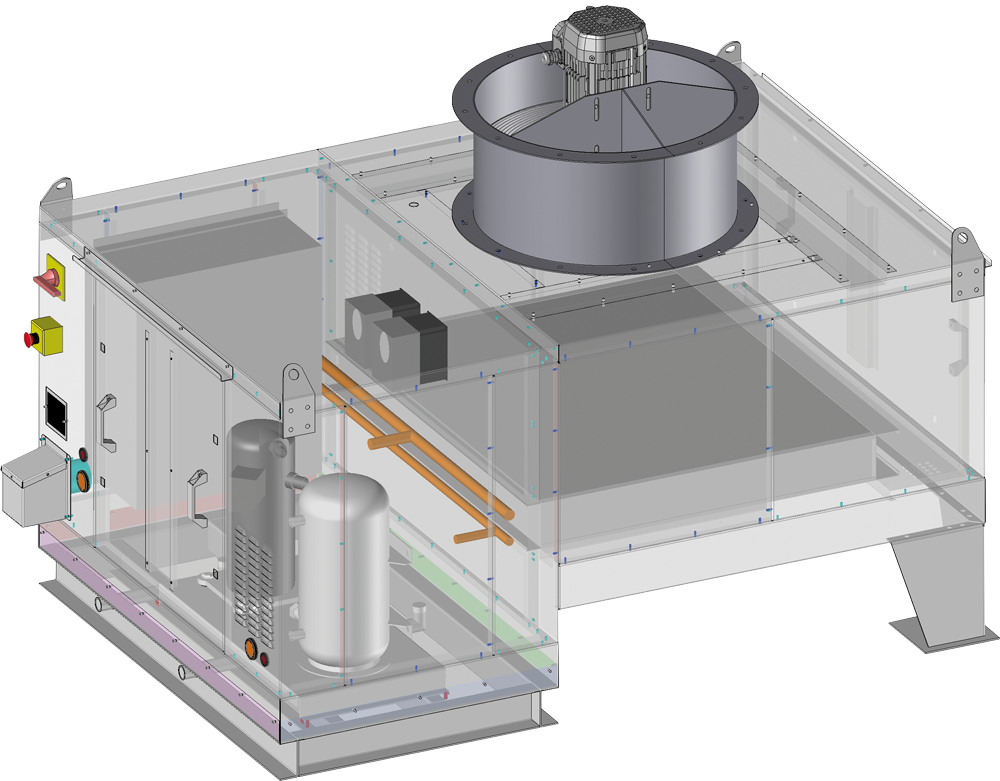

Rooftop air conditioners standard range

Adequate for non Atex zones, it can be used on shelters in “non critical” zones

- Standard unit in aluminium – stainless steel available as an option

- Refrigerant: R32, R134a or R410A

- Air flow rate from 1,500 to 30,000 m3/h

- Net cooling capacity (R410A) from 8 to 150 kW

These air conditioning systems are equipped with:

- ETT communication system for better control

- IE4 high performance plug fan

- G4-F7 filters without fibreglass

- ETT TANDEM Technology

Rooftop air conditioners special range

Adequate for Atex and non Atex zones, it can be used in zone 1 and zone 2

- Unit in aluminium or stainless steel

- Refrigerant: R134a or R410A

- Air flow rate from 1,500 to 30,000 m3/h

- Net cooling capacity (R410A) from 8 to 150 kW Sand filter available as an option

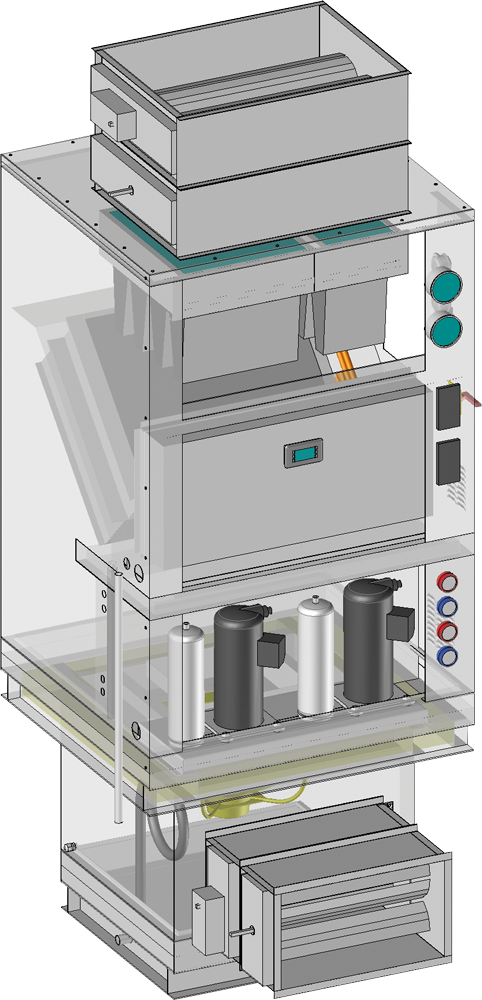

Air conditioning units (ACU) special range

Adequate for non Atex zones

- Standard unit in aluminium – stainless steel available as an option

- Refrigerant: R134a or R410A

- Air flow rate from 1,500 to 15,000 m3/h

- Net cooling capacity (R410A) from 8 to 70 kW

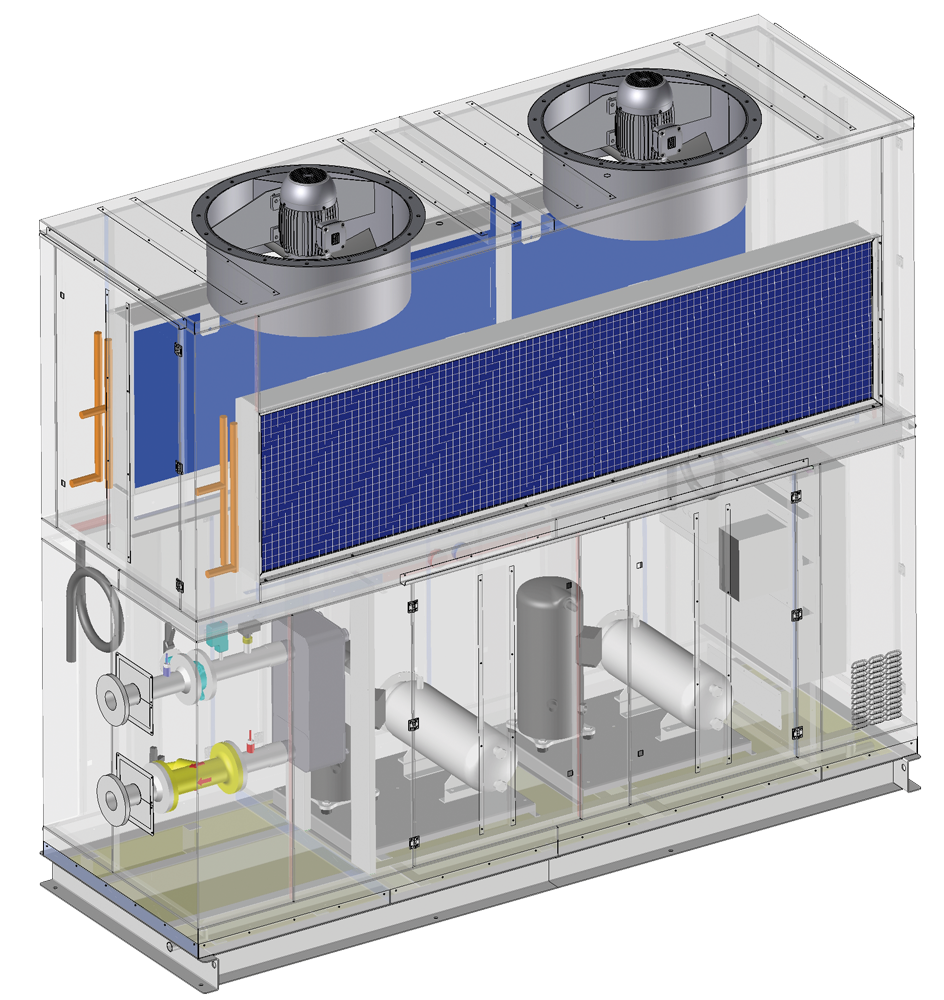

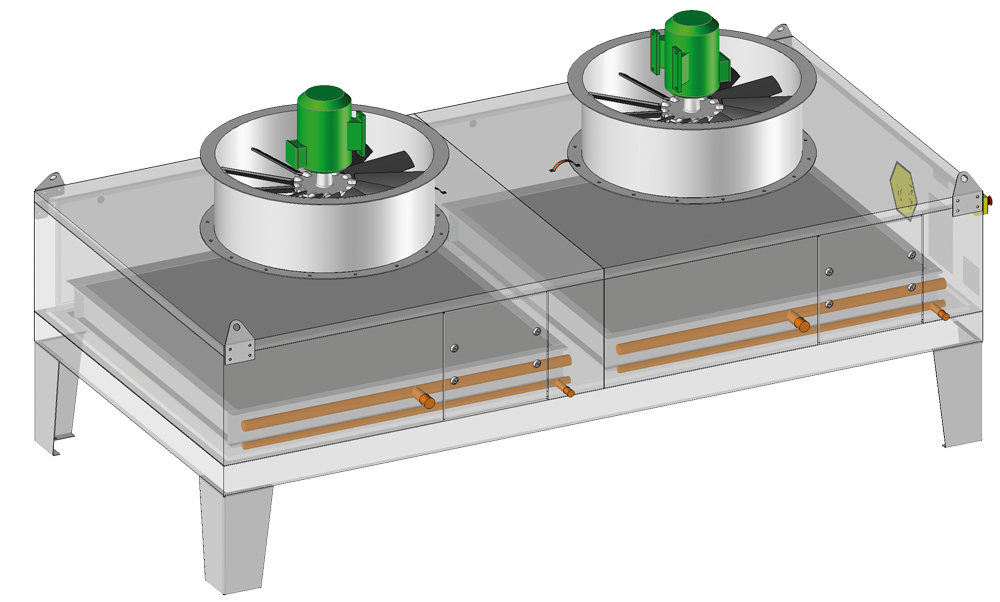

Air-cooled condensers (ACC) special range

Adequate for Atex and non Atex zones

- Standard unit in aluminium – stainless steel available as an option

- Refrigerant: R134a or R410A (hot water and coolant)

- Air flow rate from 2,000 to 28,000 m3/h

- Net heating capacity from 13 to 200 kW (R410A)

Available options:

- Batteries with special treatment

- Emergency stop switch

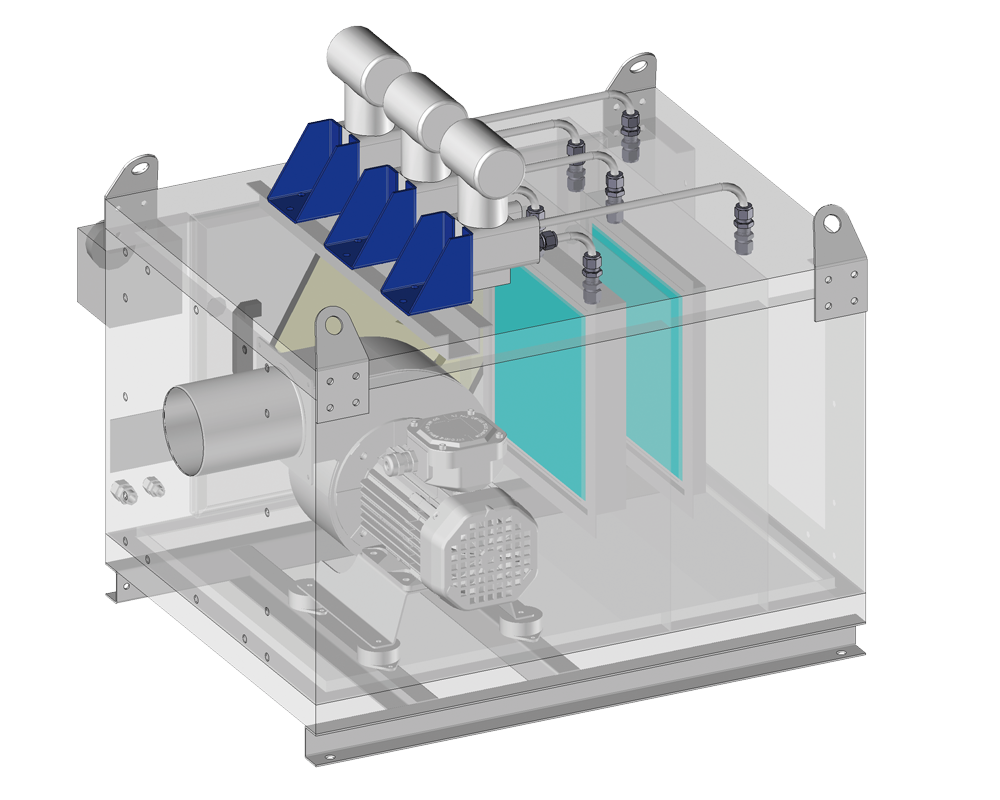

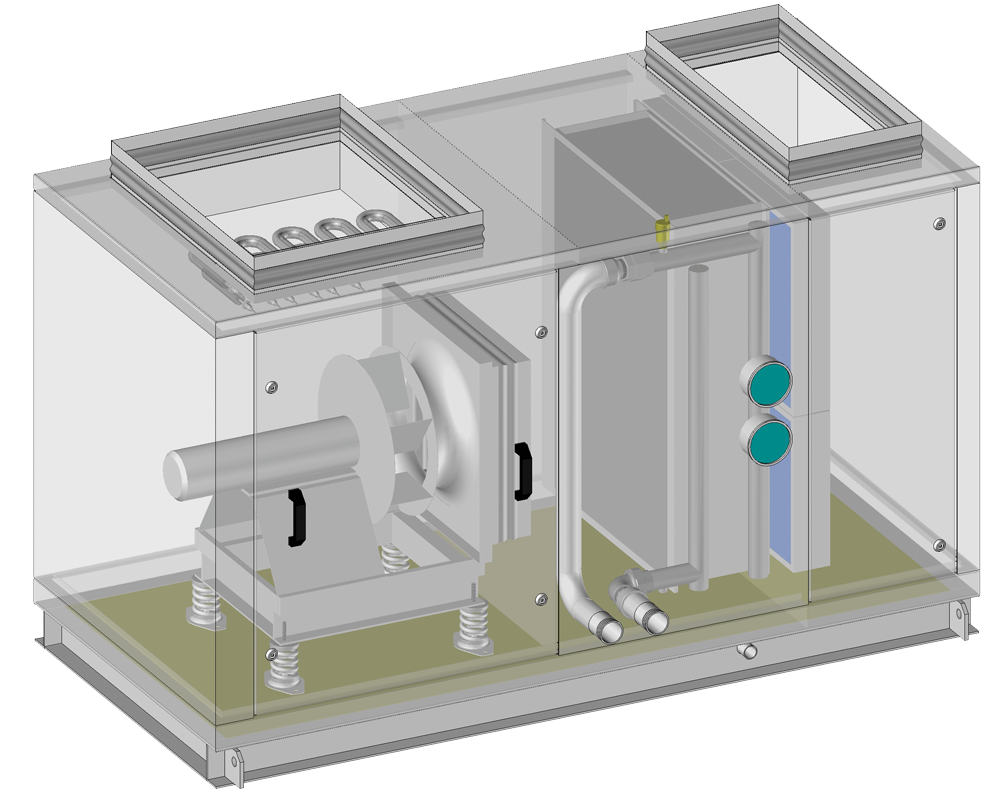

Horizontal air treatment units (ATU) special range

Adequate for Atex and non Atex zones

- Standard unit in aluminium – stainless steel available as an option

- Air flow rate from 1,000 to 50,000 m3/h

- Available components: centrifugal and axial fans, thermodynamic exchangers, electric heaters, hydraulic exchangers (hot water, chilled water, glycol water), drift eliminator, sound traps

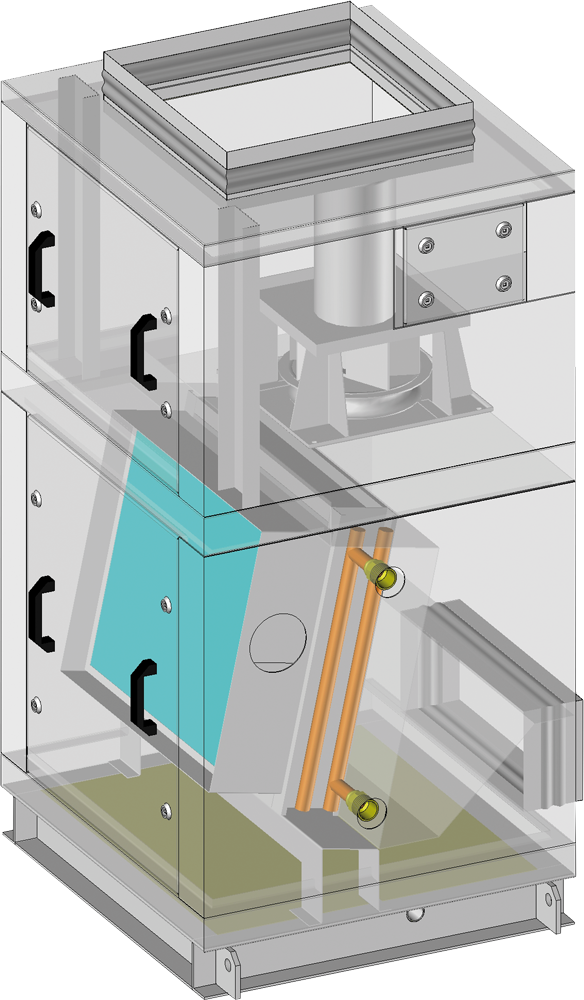

Vertical air treatment units (ATU) special range

Adequate for Atex and non Atex zones

- Standard unit in aluminium – stainless steel available as an option

- Air flow rate from 1,000 to 20,000 m3/h

- Available components: centrifugal and axial fans, thermodynamic exchangers, electric heaters, hydraulic exchangers (hot water, chilled water, glycol water), drift eliminator, sound traps

Marine cassette units special range

Adequate for non Atex zones

- Standard unit in aluminium – stainless steel available as an option

- Refrigerant: R134a or R410A (hot water and coolant)

- Air flow rate

- Net cooling capacity (R410A) from 15 to 150 kW

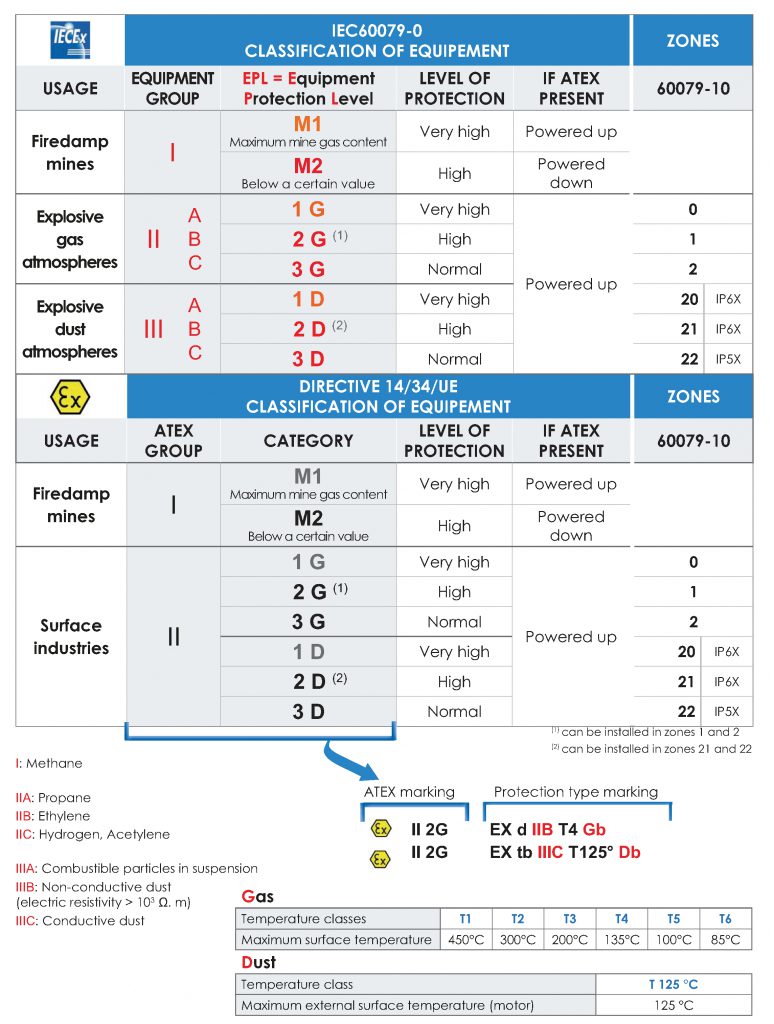

ATEX standards