Subscrib newsletter ETT

Request commissioning

ETT has developed a new generation of rooftop units: the EFFICIENCE range. This Eurovent certified range is the fruit of many years of experience in Ecodesign and modular heat pumps production.

EFFICIENCE range modular design offers you numerous possibilities. The EFFI+ DX CC+ is based on an EFFI+ packaged unit combined with an extraction module, a rotary heat exchanger module and one or more condensing boilers to adjust unit performance to the specificities and requirements of your application.

20-year guarantee against corrosion

The EFFI+ DX CC+ is a NEW GENERATION double flow heat pump with energy recovery, specifically designed for designed for ventilation, heating and air conditioning in large facilities such as superstores, warehouses, etc. This rooftop unit combines the latest technological developments to ensure optimised energy consumption.

The EFFI+ DX CC+ ventilation and air conditioning solution gives priority to energy recovery, allowing substantial energy savings in very low temperature environments. It is recommended in case of high level of fresh air inlet.

This double flow rooftop heat pump with rotary heat exchanger and condensing boilers is delivered ready to operate and can be installed either on a rooftop or at ground level depending on your needs.

Thanks to its full aluminium structure (frame & casing), this unit is covered by a20-year guarantee against corrosion (frame and casing).

The unit operates as a reversible heat pump:

- Source: outside air

- Treated fluid: inside air

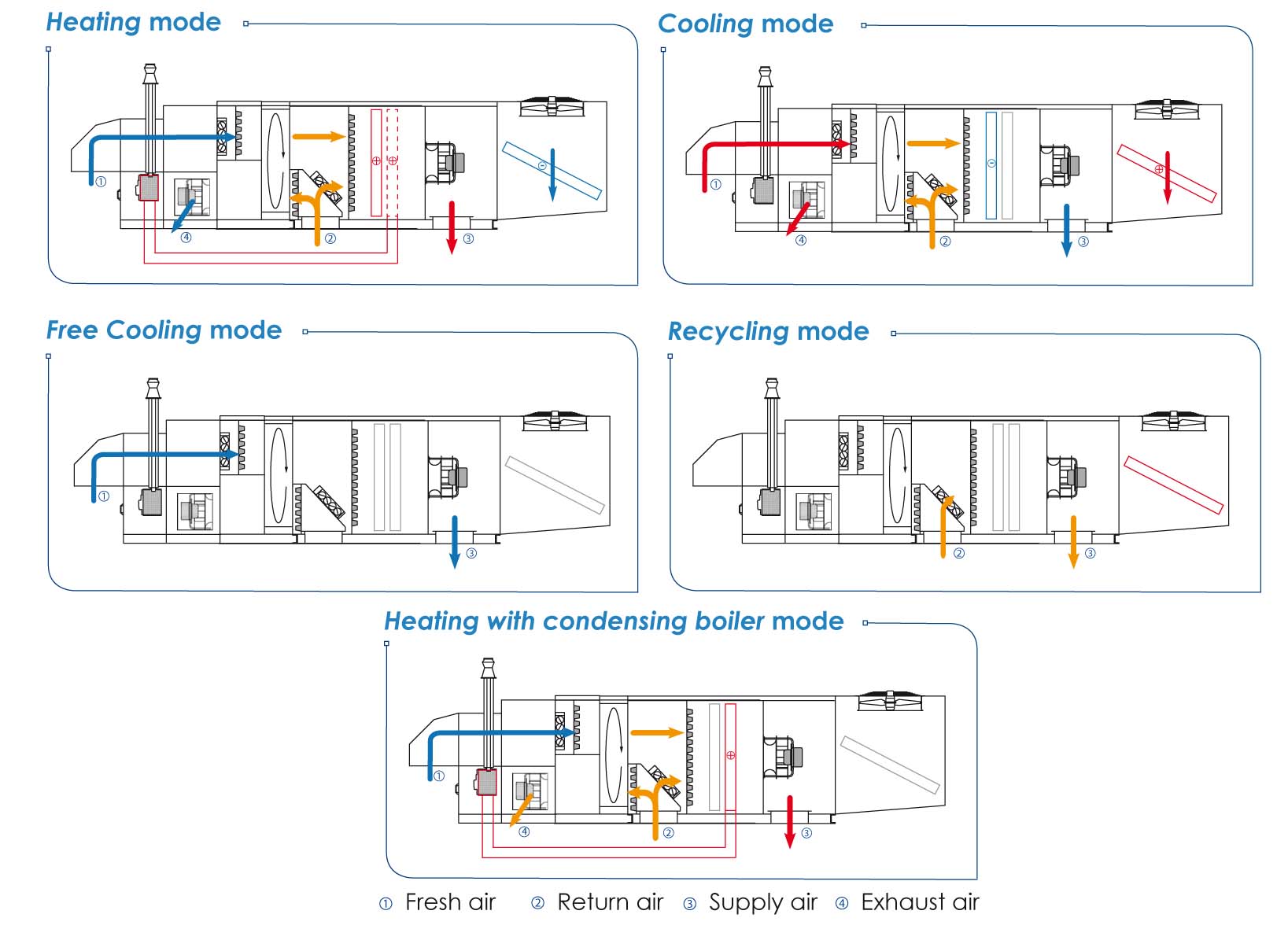

The following operating modes are available:

- heat pump

- air-conditioner

- Free Cooling with max. 50% fresh air compared to rated air flow rate

- heat pump + condensing boilers

- condensing boilers

- Heating mode: In winter, comfort temperature is maintained thanks to the thermodynamic system and the auxiliaries (optional).

- Cooling mode: In summer, comfort temperature is maintained thanks to the thermodynamic system.

-

Free Cooling mode: In mid-season, comfort temperature is maintained using in priority the difference between outside air and inside air to cool the building.

Free Cooling allows considerable savings by delaying the use of thermodynamics. - Recycling mode: Destratification through air recirculation, when return air temperature is significantly higher than room temperature.

- Heating mode with condensing boiler*: In winter, comfort temperature is maintained thanks to the condensing boiler system.

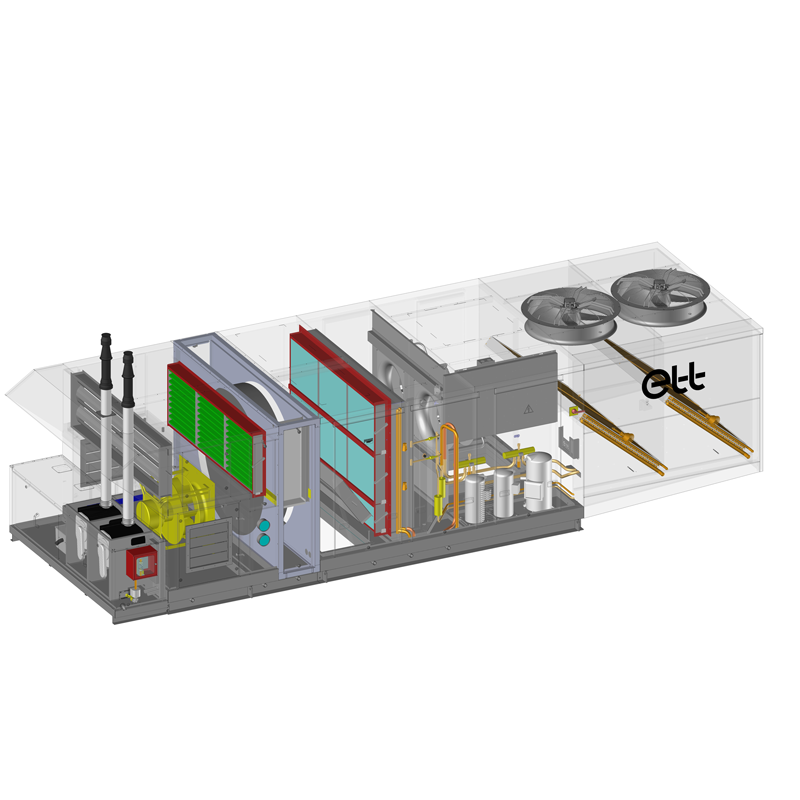

The ETT packaged unit comprises 4 different sections:

- The external section allows thermal exchanges with the environment.

- The separate technical section houses the refrigeration components, the electrical board and the control components.

- The internal section ensures the air change and air treatment.

- The separate technical section houses the condensing boiler(s) and the control components.

Frame – Casing

- Unit with Vertical (V) or Lateral (L) supply air

- Motorised external damper for supply air (2006/42/EC Directive)

- Double skin, 13/10 AG in internal section, 50 mm

Acoustics

- Technical section acoustic insulation using STOPFLAM flexible fire-proof polyurethane foam

- Exhaust air box sound insulation

- Fresh air cowl sound insulation

- Compressors sound jackets

Air handling

- Filtration pressure gauge

- Analog air flow controller (AFC), air flow rate indication and measurement

- Filters fouling analogue control (FFAC)

- Self-contained smoke detector backed-up or not

- Epoxy coating for wheel + fans & Vinyl coating for exchangers

- Supply air fan available pressure: 400 Pa max.

- G4 refillable filters, 98 mm thick

- F7 or F9 opacimetric filters, 98 mm thick

- G4 + F7 or F9 double filters (48 + 48 mm)

- High pressure supply air fans kit available for high available pressure

- Operation in all recycling mode

- G1 metal filters (23 mm thickness) in fresh air mode

Thermodynamics

- HP and LP pressure gauges

- Electronic expansion valves

- Cooling operation only

- Refrigerant leak detection aid

Thermal exchangers

- Year-round kit

- Recovery coil on food refrigeration (water)

- Vinyl coating on recovery coil

Electricity

- Unit global energy metering

- Aluminium/copper connection terminal blocks (aluminium mandatory for power cables)

- Soft starter (compressors current soft starter)

- 230 V/16 A single-phase socket in the technical section (separate power supply to be provided by the installer)

Control

- Min. fresh air slaving using turret contacts (2 maximum)

- Year-round operation (allows compressor operation in cooling mode with -5°C < outside T° < +15°C)

- Banning of Free Cooling using specific humidity comparison

- Humidity probe (for external humidifier control)

- Average room temperature (4 probes)

- ETT SRV (Variable Cooling System) control, compressor with electronic expansion valves.

Laying

- Aluminium adjustable connection roof curb

- Aluminium adjustable adaptation roof curb

- Aluminium adjustable ventilated roof curb

- Aluminium ventilated adaptation roof curb

- Aluminium plenum for return air and supply air

- 200 or 400 mm aluminium feet

Gas

- Expansion valve 300 mbar – 20 mbar and gas stop valve

- Safety gas box with glass window (mandatory for PAB)

- Gas meter