Description

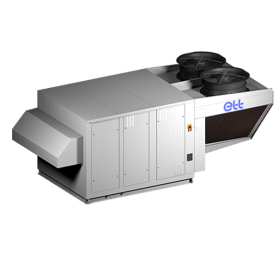

The ULTI+ R32 DX+ belongs to the ULTIMA Green Line, a modular range of next-generation rooftops from ETT. It combines quality materials, performance, energy savings, acoustics, regulation and new-generation connected components to ensure that the units operate at optimum efficiency at all times.

An unrivalled product line-up (flow rates/power) that perfectly meets the weight and space constraints of existing units to be replaced.

Thanks to its full aluminium structure (frame & casing) that ensures an excellent corrosion protection, this air conditioning and heating system is covered by a 20-year guarantee against corrosion (frame and casing).

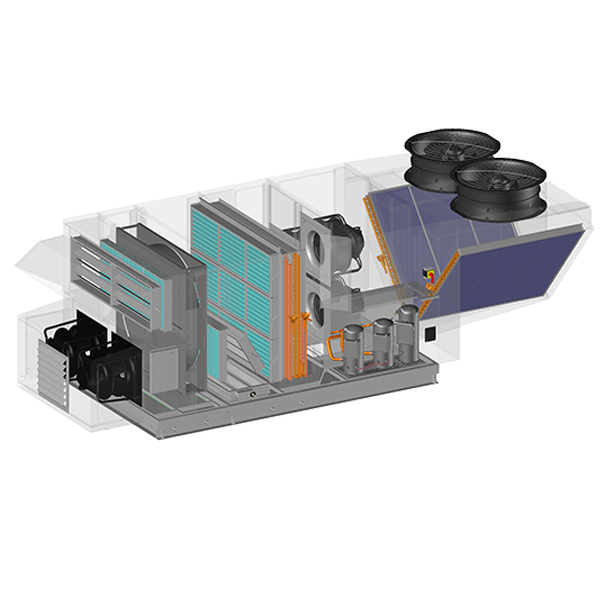

This single flow rooftop heat pump is delivered ready to operate. A separate technical compartment facilitates unit control and maintenance and allows measurement and adjustment during operation.

The ULTI+ R32 DX is designed to provide precise regulation, adapting the rotational speeds of the power stages, for optimum, continuous energy performance throughout its years of operation.

This rooftop comes with a 5-year basic warranty and all ETT services: Commissioning, Audits, Service contracts etc.

Products top benefits

- Grande plage de débit et de puissance disponible

- R32 refrigerant

- Extraction and recovery module

- ERP2021