Description

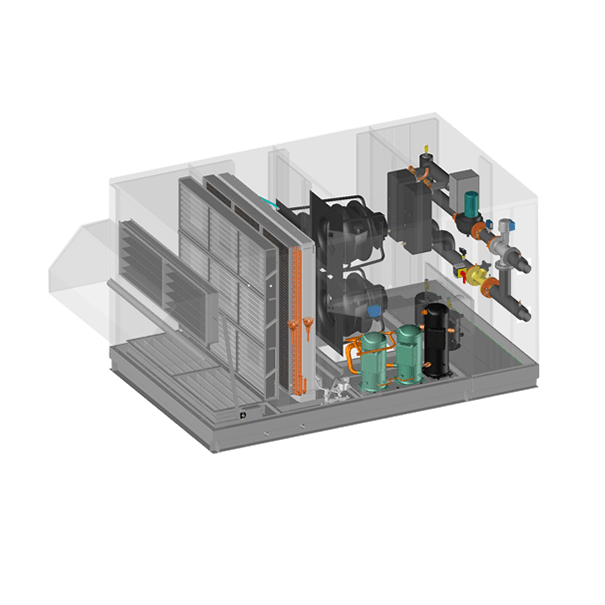

The ULTI+ R32 ADIA OR is an evolution of ETT’s latest-generation rooftop range. It has been developed on the basis of the EUROVENT-certified ULTI+ R32 range, and is the subject of a patent application. It combines quality materials, , energy savings, acoustic performance, control and new-generation connected components, enabling the units to operate at optimum efficiency at all times

The combination of thermodynamic and direct adiabatic technologies means that energy consumption is kept to a minimum, while ensuring that indoor comfort requirements are met at all times, whatever the climatic conditions outside.

In hot weather, the high-efficiency adiabatic function takes priority over compressor activation. Thanks to specific regulation (artificial intelligence), cooling periods by evaporation are by far the majority, which means we can benefit from the environmental and economic advantages of water as a refrigerant.

This rooftop comes with a 5-year basic warranty and all ETT services: Commissioning, Audits, Service contracts etc.

Products top benefits

- Water-cooled rooftop with adiabatic module

- R32 refrigerant (Low GWP)

- Wide range of water rates and power available

- Water loop operation