Description

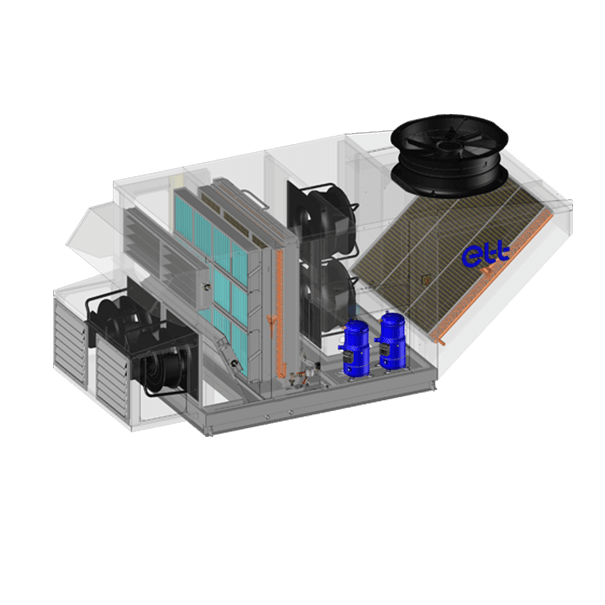

The ULTI+ R32 ADIA EX2 is an evolution of ETT’s latest-generation Rooftop range. It has been developed on the basis of the EUROVENT-certified ULTI+ R32 range, and is the subject of a patent application. It combines quality materials, , energy savings, acoustic peformance, regulation and next-generation connected components, to allowing the units to operate optimally at all times. The combination of thermodynamic and direct adiabatic technologies means that energy consumption is kept to a minimum, while ensuring that indoor comfort requirements are met at all times, whatever the climatic conditions outside.

Thanks to its full aluminium structure (frame & casing) that ensures an excellent corrosion protection, this air conditioning and heating system is covered by a 20-year guarantee against corrosion (frame and casing).

This single flow rooftop heat pump is delivered ready to operate. A separate technical compartment facilitates unit control and maintenance and allows measurement and adjustment during operation.

The ADIA is designed to provide precise regulation, adapting the rotational speeds of the power stages, for optimum, continuous energy performance throughout its years of operation.

This rooftop comes with a 5-year basic warranty and all ETT services: Commissioning, Audits, Service contracts etc.

Products top benefits

- Wide range of water speeds and power available

- Fluid R32

- Patented solution

- Energy gain of 60% to 71%