Descriptif

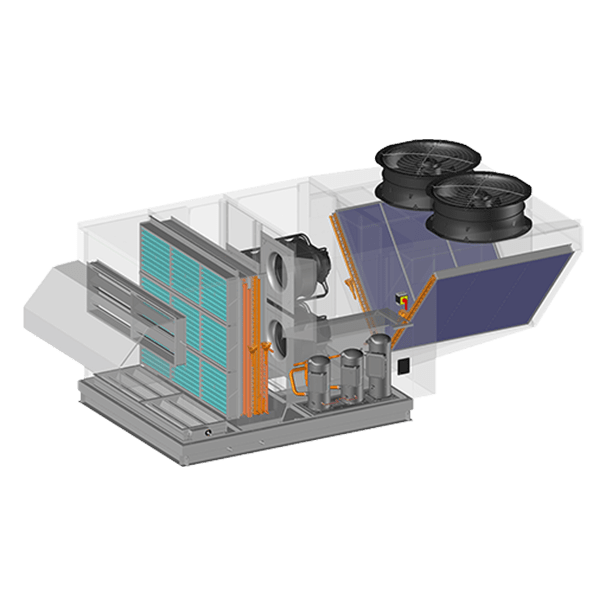

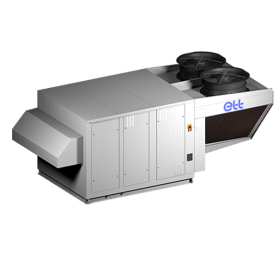

L’ULTI+ R290 ADIA est une évolution de la gamme de rooftop de dernière génération d’ETT. Elle est développée sur la base de la gamme ULTI+ R290, et fait l’objet d’un dépôt de brevet. Elle allie qualité des matériaux, économies d’énergie, performances acoustiques, régulation et composants connectés de nouvelle génération permettant aux unités de fonctionner constamment de façon optimale. L’association des technologies thermodynamique et adiabatique direct permet de minimiser les consommations énergétiques tout en assurant en permanence les exigences de confort intérieur et ce, quelles que soient les conditions climatiques extérieures.

Réalisé à partir d’une structure entièrement en aluminium (châssis et carrosserie) lui conférant une tenue à la corrosion particulièrement efficace, ce système de climatisation et de chauffage est garanti 20 ans anticorrosion (châssis – carrosserie).

Cette pompe à chaleur de toiture simple flux est livrée prête à fonctionner. Un compartiment technique séparé facilite la maintenance et le pilotage de l’unité et permet d’effectuer des mesures et d’affiner les réglages en fonctionnement.

De par sa conception, l’ULTI+ R290 ADIA permet d’obtenir une régulation précise, adaptant les vitesses de rotation des étages de puissance, pour une performance énergétique optimale et continue pendant toutes ses années de fonctionnement.

Garanti 5 ans de base, ce Rooftop bénéficie de tous les services ETT : Mise en service, Audits, Contrats de services …

Les + produits

- Fluide R290 (Faible GWP : 0.02)

- Solution brevetée

- Gains énergétiques de 60% à 71%