Descriptif

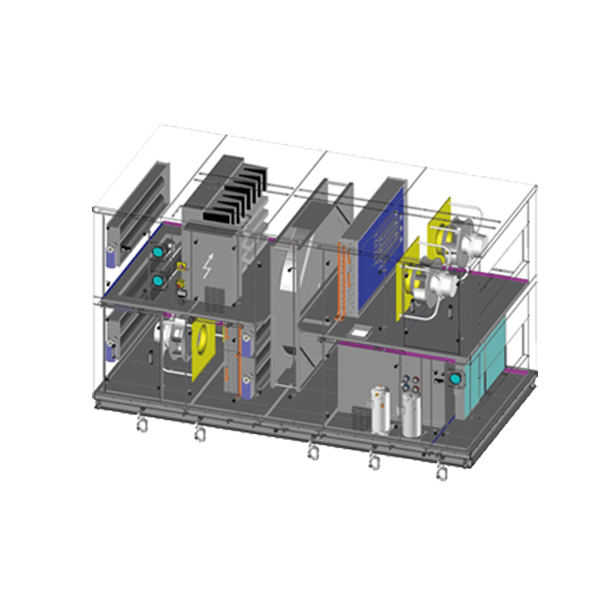

La pompe à chaleur double flux rooftop PACARE est spécialement conçue pour le traitement et la préparation d’air neuf dans les bâtiments à basse consommation. Cette unité autonome de toiture avec récupération d’énergie associe un système de refroidissement adiabatique indirect et un récupérateur à double passe pour une consommation d’énergie optimale.

Réalisé à partir d’une structure entièrement en aluminium (châssis et carrosserie) lui conférant une tenue à la corrosion particulièrement efficace, ce système de climatisation et de chauffage est garanti 20 ans anticorrosion (châssis – Carrosserie).

Cette pompe à chaleur de toiture double flux est livrée prête à fonctionner et s’installe indifféremment en toiture ou au sol. La conception et le choix des composants utilisés dans nos pompes à chaleur permettent de garantir une fiabilité importante.

Garanti 5 ans de base, ce Rooftop bénéficie de tous les services ETT : Mise en service, Audits, Contrats de services …

Les + produits

- Echangeur de récupération rotatif haut rendement

- Accès sur une face

- Grande plage de débit et de puissance disponible