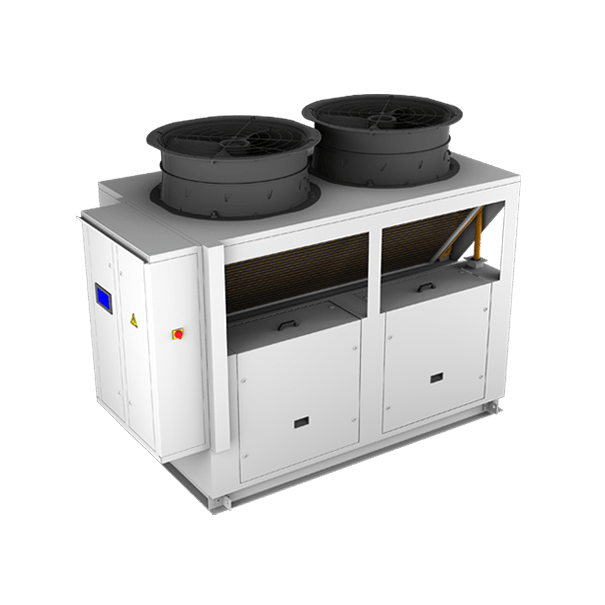

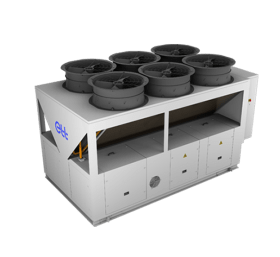

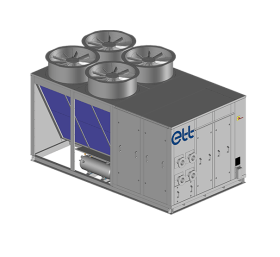

Description

The Neromax range is one of the solutions available for decarbonising heat production.

Thanks to its full aluminium structure (frame & casing) that ensures an excellent corrosion protection, this air conditioning and heating system is covered by a 20-year guarantee against corrosion (frame and casing).

Thanks to its full aluminium structure (frame & casing), the NEROMAX HT unit is covered by a 20-year anti-corrosion warranty.

This rooftop comes with a 5-year basic warranty and all ETT services: Commissioning, Audits, Service contracts etc.

Products top benefits

- Air-to-water heat pump for hot water production

- Very low noise level

- Decarbonisation: new R290 natural fluid (GWP 0.02) compliant with F-GAS 2027

- A wide range of integrated hydraulic options