Description

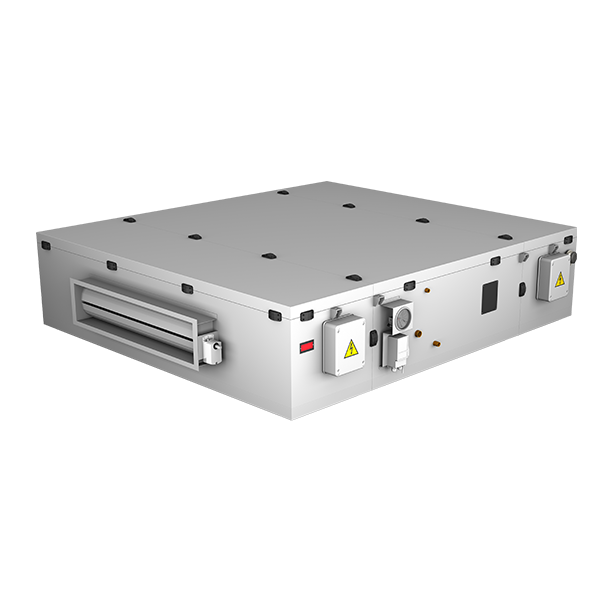

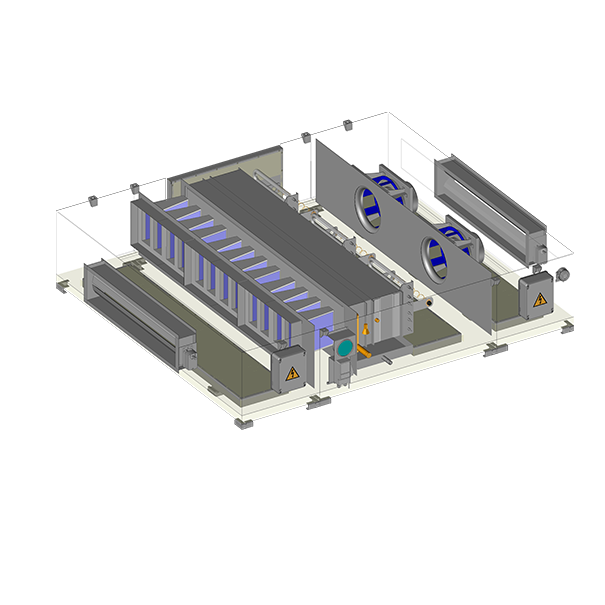

ETT’s flat air handling unit, delivered ready to operate, is constructed from a base structure made entirely of AG3 aluminium (frame and casing), or optionally from AG4 marine aluminium or 316 L stainless steel (grade 1.4404), giving the FCU range particularly effective corrosion resistance.

Designed for maximum compactness, the unit can be integrated into E-House layouts, with with ceiling or raised floor mounting.

Although primarily intended for indoor use, its construction also permits outdoor installation.

The FCU comes with a 20-year anti-corrosion warranty (frame and casing).

Standard one-year warranty is included, with availability of full ETT services : Commissioning, Audits, Service contracts etc.

Products top benefits

- Compactness

- Corrosion Resistance

- Wide range of options