Description

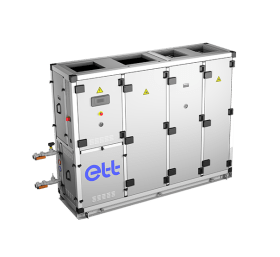

With a wealth of experience in the field of dehumidification in France and for export, ETT offers you a new generation of dehumidifier The DESHU HPE+ becomes the DESHU XP+.

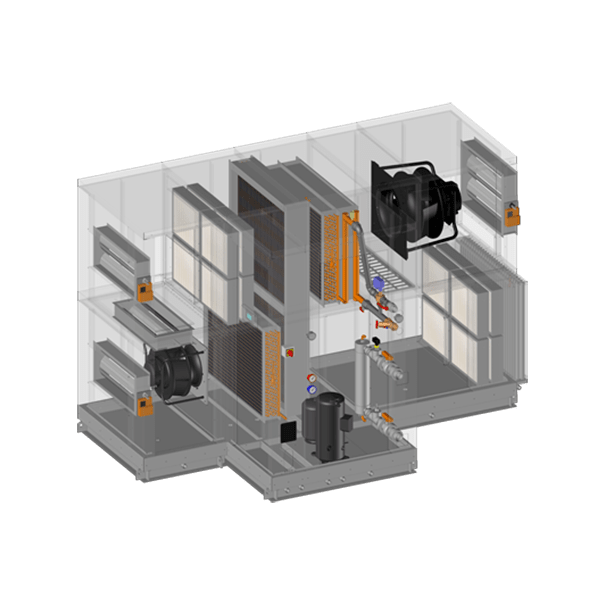

The DESHU XP+ is an improved machine with increased capacities and new options to meet the dehumidification needs of swimming pools and spas.

Manufactured using an all-aluminium structure (frame and casing) for particularly effective corrosion resistance, this air conditioning and heating system comes with a 20-year anti-corrosion guarantee (frame- casing).

This dehumidifier comes with a 5-year basic warranty and all ETT services: Commissioning, Audits, Service contracts etc.

Products top benefits

- Dehumidification by thermodynamics and fresh air (double-flow air handling unit)

- Ease of installation: multi-block delivery possible

- Decarbonation

- Cooling by integrated cycle reversal in the single-block unit