Description

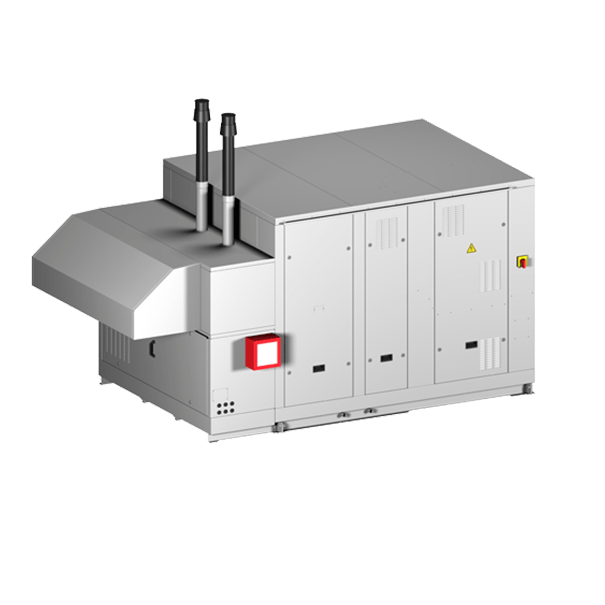

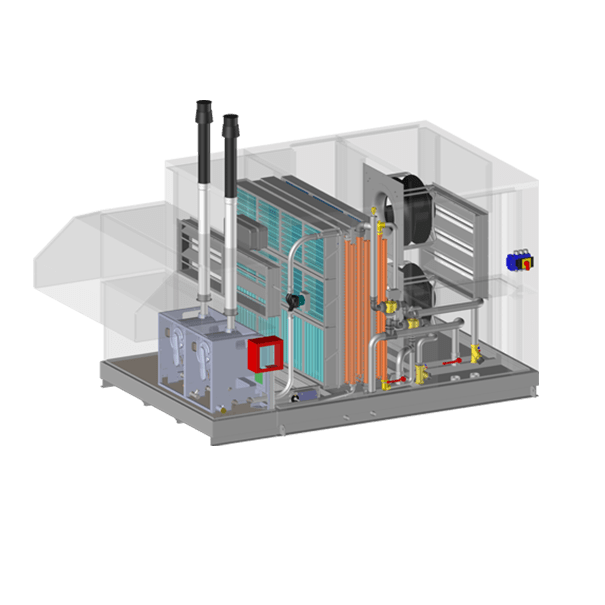

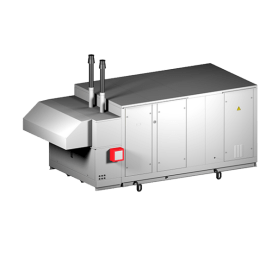

The CTA ULTI+ CC+ is ETT’s new modular range of latest-generation AHUs. It combines quality materials, acoustic performance, energy savings, regulation and new-generation connected components, enabling the units to operate at optimum efficiency at all times.

Thanks to its full aluminium structure (frame & casing) that ensures an excellent corrosion protection, this air conditioning and heating system is covered by a 20-year guarantee against corrosion (frame and casing).

This AHU comes with a 1-year basic warranty and all ETT services: Commissioning, Audits, Service contracts etc.

Products top benefits

- Air handling

- AHU