Description

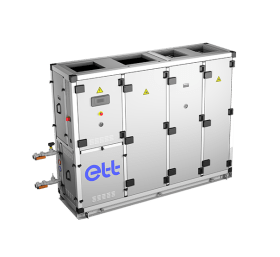

Manufactured using an all-aluminium structure (frame and casing) for particularly effective corrosion resistance, this dehumidification system comes with a 20-year anti-corrosion warranty (frame- casing).

This dehumidifier comes with a 5-year basic warranty and all ETT services : Commissioning, Audits, Service contracts etc.

Products top benefits

- Dehumidification achieved by thermodynamic cooling coupled with fresh air modulation

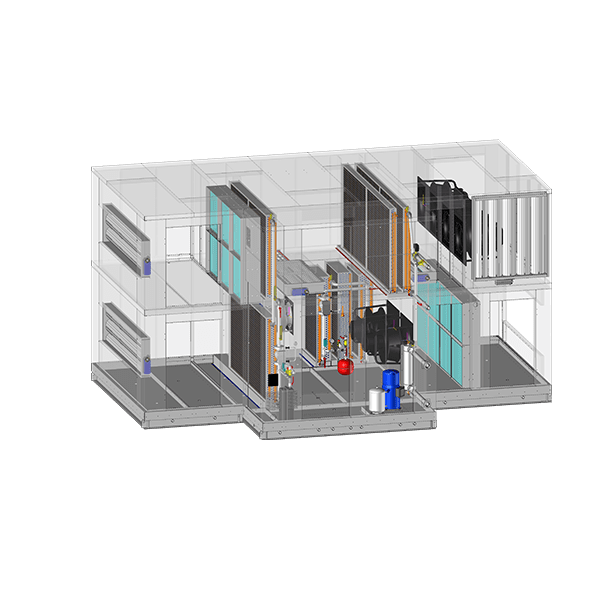

- Easy installation: multi-block or split delivery available

- Decarbonisation: new R513A fluid & high-performance energy recovery unit (efficiency > 68%)