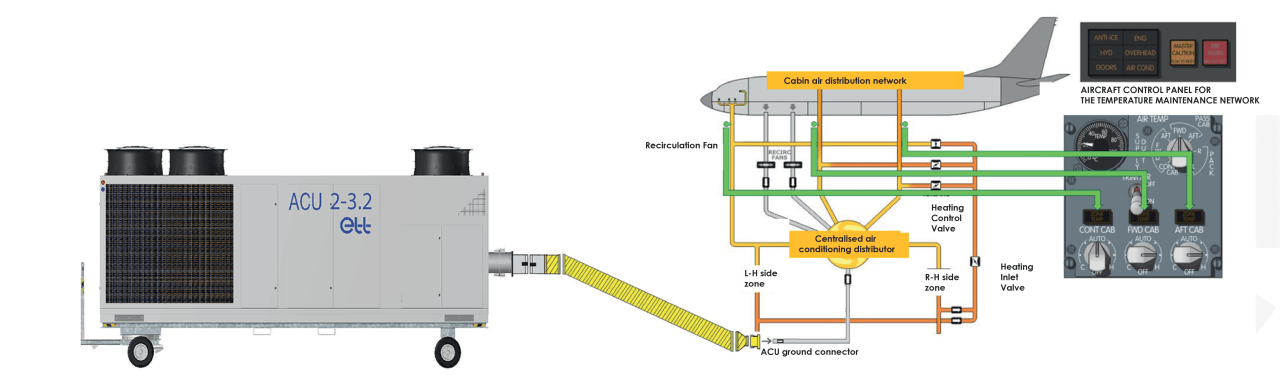

Description

The ACU is designed to provide precise regulation for optimum, continuous energy performance.

The ACU range uses R513A refrigerant. This choice is best suited to the requirements of the aeronautical and airport sectors.

Its main advantages are:

- A low Global Warming Potential (GWP) of 631 which puts it below the threshold of 750 imposed by the European F-GAS III 2024 regulation.

- A non-flammable fluid with little or no toxic effect: R513A is classified A1 group L1. A coherent choice to combine carbon impact reduction and safety for our applications in the specific environment of an airport runway.

- Performance adapted to airport conditions: its application range ensures optimal performance even when outside temperatures are at their highest (operation up to 50°C or even 60°C outside).

Manufactured using an all-aluminium structure (frame and casing) for particularly effective corrosion resistance, this air conditioning and heating system comes with a 20-year anti-corrosion guarantee (frame- casing).

This heat pump is delivered ready to operate. A separate technical compartment facilitates unit control and maintenance by allowing measurement and adjustment during operation.

The ACU is designed to provide precise regulation, adapting the rotational speeds of the power stages, for optimum, continuous energy performance throughout its years of operation.

It comes with a 2-year basic warranty and all services ETT: Commissioning, Audits, Service contracts etc.

Products top benefits

- Temperature / flow / pressure performance

- Maintain supply temperature at 02°C without defrosting

- Wide range of flow rates and power ratings

- Fixed and mobile version