Understanding your warehouse challenges

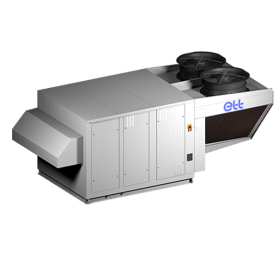

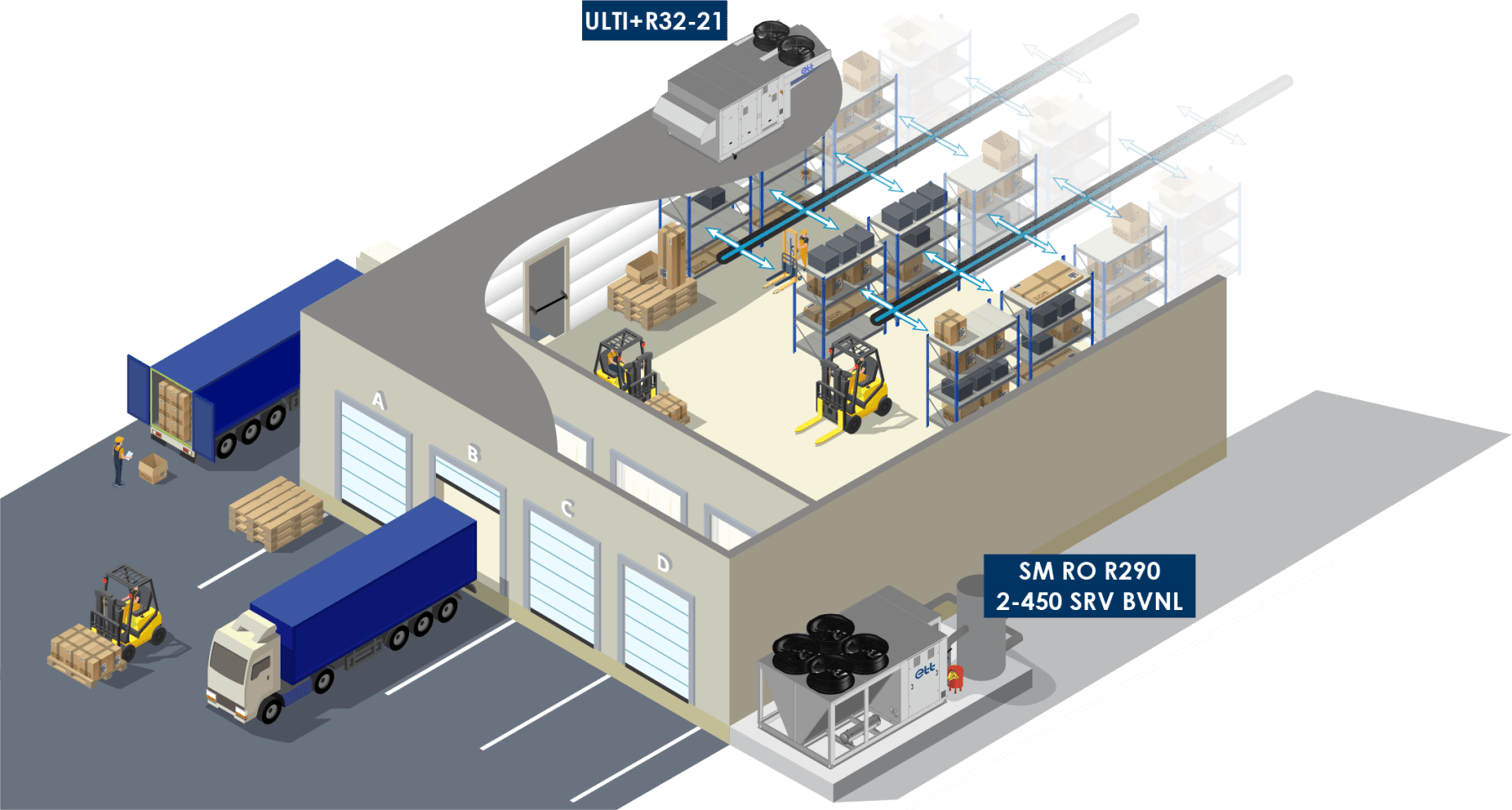

ETT, air treatment adapted to all types of warehouses

Whatever your needs for optimising worker comfort and storage quality in your warehouses, ETT designs and manufactures solutions to meet your various requirements:

- Humidity control: uncontrolled humidity is more than harmful in storage warehouses, as it can lead to spoilage of goods, the development of mould and the deterioration of your buildings.

ETT provides dehumidification and air treatment solutions tailored to your specific needs:

- Air quality: The supply of fresh air is essential for all storage warehouses. Constant renewal of air quality prevents the spread of bacteria and the development of mould.

ETT can advise you on low-energy ventilation solutions.

- Large-area heating: It is essential to maintain a constant and adequate level of heat in your storage areas in order to preserve stored items and protect workers in the field.

ETT air handling solutions are designed for large volumes.

- Heat control: Unregulated heat and temperature extremes (too low or too high) can easily make conditions difficult in warehouses.

Keep conditions cool and teams productive with ETT's high-performance solutions.

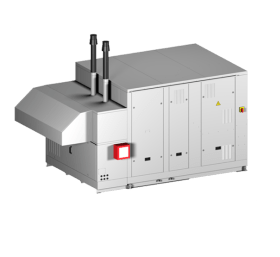

ETT's solutions for meeting the aeraulic and economic challenges of warehouses include various functions.

Dehumidification by thermodynamic system or desiccation. Using thermodynamics, the heat can be used to heat the air or any other process effluent.

ETT recommends desiccation for any requirement involving a water weight of less than 6 g in the supply air stream.

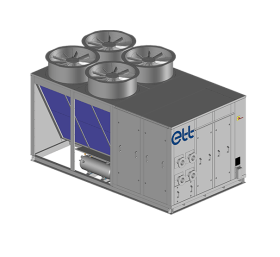

For hot water heating systems, the use of air-to-water or water-to-water heat pumps to replace gas boilers has the dual advantage of significantly reducing the site's carbon footprint while reducing energy bills.

In addition to integrated heating and cooling via our thermodynamic system, it's possible to add supplementary equipment such as:

- Condensing gas modules

- Direct or indirect adiabatic coolers

- Chilled water, hot water, steam or CO2 coils

- Electric preheating, heating and auxiliary coils

Many industrial applications require ambient humidity regulation. This involves implementing equipment to dehumidify or humidify the air, such as:

- Thermodynamic or desiccant dehumidification

- Steam humidification with or without integrated production

Energy efficiency is a key concern for manufacturers. To this end, ETT can integrate various equipment and control features such as: Thermal wheels, plate heat exchangers, heat pipes, glycol coils.

Recent regulatory developments, particularly the F-Gas regulation, strongly encourage the use of natural refrigerants.

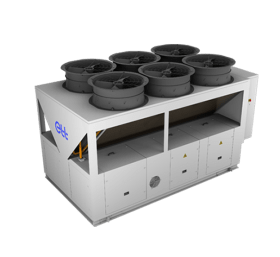

For several years, ETT has been incorporating Propane (R-290) as a refrigerant in various types of machines (air and water-based) such as:

- Air-to- Air heat pumps

- Chillers up to 1.2 MW

- Heat recovery chillers

- High temperature heat pumps up to 70°C

This ETT innovation, combined with a heat pump, meets the need to reduce consumption while maintaining summer comfort.

The control system adapts the machine's operation in real time to optimise energy consumption.

Special attention must be paid to equipment control to meet manufacturers' expectations. This is why ETT develops all of its algorithms to offer customized operation.

Additionally, the myETTvision supervision tool allows manufacturers to monitor their machines remotely and in real-time.

New build

Refurbishment

Dedicated solutions

Need support for your existing installation?

Expertise dedicated to the storage warehouse

The total surface area of warehouses in France is close to 78 million square metres, enabling a high level of storage of goods in the transport circuit.

The average size is 18,500 m2. The largest 10% (those with a surface area of over 35,000 m²) account for almost 40% of the total surface area.

ETT solutions enable you to meet requirements in terms of air quality, temperature maintenance, controlled hygrometry and low energy consumption for warehouse surfaces in excess of 35,000 m².

Regulations

The new decree, which implements the provisions of the ELAN law, requires buildings to reduce their energy consumption by 40% by 2030. It applies to all logistics sites, regardless of size, from 1,000 m² upwards.

The 2020 environmental regulations are gradually replacing the previous thermal regulations in France. They continue to aim to improve energy performance, reduce the energy consumption of new buildings and improve comfort, but they also address the issue of carbon impact.