Understanding your industry challenges

Technical textile factories have specific needs that differ from traditional textile factories due to the advanced and specialized nature of their products.

High-precision weaving or knitting machines require very specific air quality, especially for fibres such as aramid, carbon, polypropylene, and polyester.

The same applies to coating, laminating, and surface treatment applications during specific chemical treatments to improve textile properties (heat resistance, anti-UV, etc.).

ETT, recognized as an air treatment specialist, will be able to assist you in designing the best technical solution.

The main objective is to adapt to technological developments and market requirements to maintain their competitiveness and meet the varied needs of customers.

Textile manufacturing workshops are subject to various constraints related to worker comfort, which can directly influence productivity, work quality, and the general well-being of employees.

Due to its strong experience in this field, ETT has become a reference in the design and manufacture of autonomous air treatment machines. The challenges focus on three key points:

- Control geared to operator comfort

- Particular attention to air diffusion

- A very reduced noise level

Textile dyeing factories face unique environmental challenges in ensuring product quality, worker safety, and compliance with environmental regulations.

Temperature control is critical for maintaining dye and treatment quality. Even slight temperature fluctuations can lead to colour inconsistencies and defects in the final product.

Humidity levels also play a crucial role, influencing how dyes penetrate and bond with textile fibres. Improper humidity can result in colour variations and fixation issues.

Effective ventilation is paramount in these facilities. It's essential for removing solvent vapours and chemical fumes used in dyeing processes. Poor ventilation not only poses health risks to workers but can also compromise product quality.

Ventilation systems must be designed to provide adequate air exchange while minimizing workers' exposure to potentially hazardous substances.

Controlling airborne particles, dust, and contaminants is another key factor. These elements can interfere with dyeing processes and impact the quality of finished products if not properly managed.

Implementing effective energy management strategies helps reduce costs and carbon footprint. Additionally, heat recovery systems can optimize energy use in the dyeing process by reclaiming heat from exhaust air and wastewater.

Clothing and fashion accessory factories have diverse energy needs depending on their production processes, facility size, and technologies used.

Well-designed ventilation and air conditioning systems are crucial for maintaining comfortable and safe working conditions.

Special attention must be given to certain processes, such as garment pressing to remove wrinkles or heat treatments used to set dyes or patterns. These processes often require heat sources that need careful management to ensure both efficiency and safety.

Textile factories rely on the same energy-intensive equipment as laundries for washing and drying processes. To address this, ETT offers high-efficiency, decarbonized solutions that can significantly reduce energy consumption and environmental impact.

ETT solutions that meet textile challenges integrate different functions.

In addition to integrated heating and cooling via our thermodynamic system, it's possible to add supplementary equipment such as:

- Condensing gas modules

- Direct or indirect adiabatic coolers

- Chilled water, hot water, steam or CO2 coils

- Electric preheating, heating and auxiliary coils

Many industrial applications require ambient humidity regulation. This involves implementing equipment to dehumidify or humidify the air, such as:

- Thermodynamic or desiccant dehumidification

- Steam humidification with or without integrated production

Energy efficiency is a key concern for manufacturers. To this end, ETT can integrate various equipment and control features such as:

- Thermal wheels, plate heat exchangers, heat pipes, glycol coils

- Free cooling management

Managing air flow is essential for proper industrial process operation:

- Air turnover rate / homogenization of temperature and humidity conditions

- Fresh air compensation (process extraction)

- Positive or negative air pressure management

- High pressure air supply

Numerous constraints often require machines to be designed for integration into their environment. ETT's flexibility allows for:

- Custom dimensions and multi-block design

- Reinforced casing

- Anti-corrosion treatment of components and casing for harsh environments

- Aluminum or STAINLESS STEEL casing, paint finish

- Adaptation to acoustic constraints

Air quality is an important factor for operator comfort and production quality, requiring equipment for:

- Particle and molecular filtration

- Fresh air management

- ATEX (explosive atmosphere) risk management

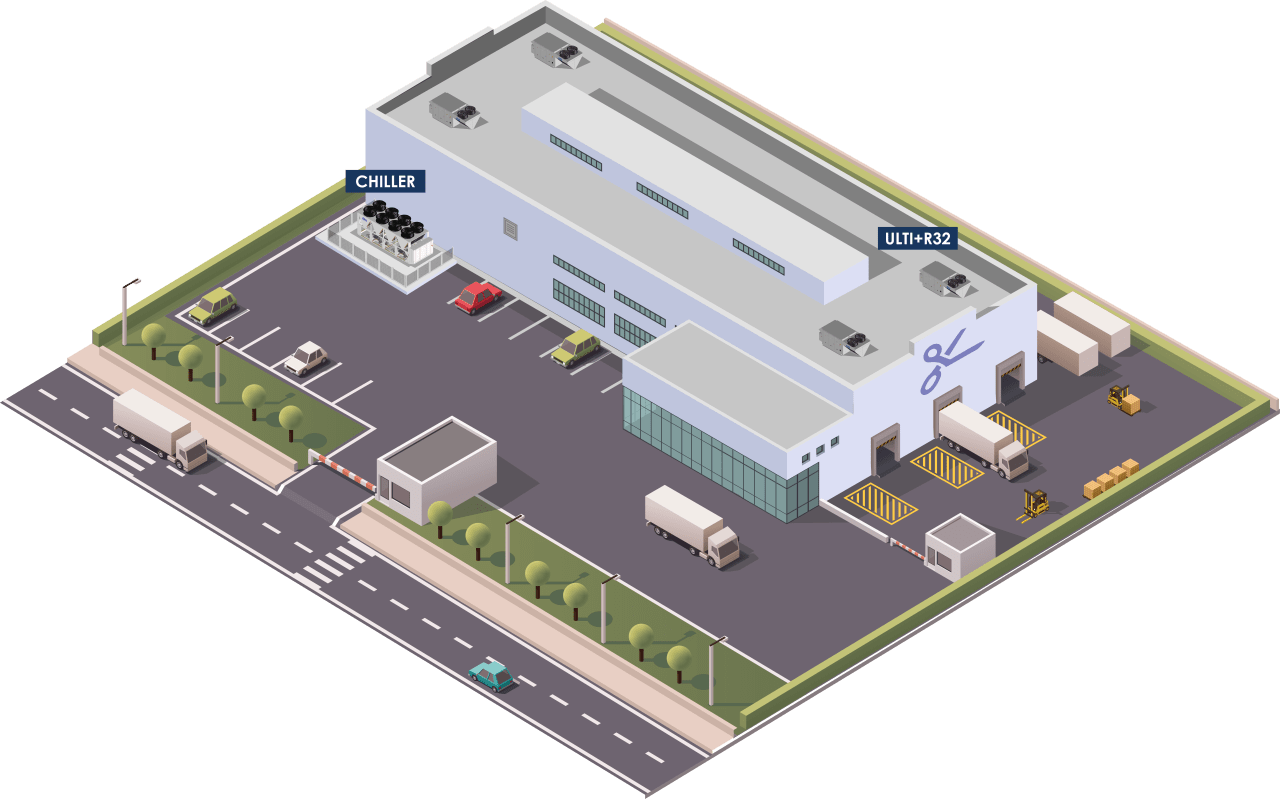

Recent regulatory developments, particularly the F-Gas regulation, strongly encourage the use of natural refrigerants.

For several years, ETT has been incorporating Propane (R-290) as a refrigerant in various types of machines (air and water-based) such as:

- Air-to- Air heat pumps

- Chillers up to 1.2 MW

- Heat recovery chillers

- High temperature heat pumps up to 70°C

Special attention must be paid to equipment control to meet manufacturers' expectations. This is why ETT develops all of its algorithms to offer customized operation.

Additionally, the myETTvision supervision tool allows manufacturers to monitor their machines remotely and in real-time.

Your project ?

New build

Refurbishment

Dedicated solutions

In pictures

Have a question ?

A project ?

High-performance, sustainable solutions for the clothing industry

The textile industry in France is a significant sector covering a wide range of activities, from the production of fibres to the manufacture of clothing and textile articles.

The textile sector in France generates annual sales of around €20 billion. This figure includes textile production, clothing manufacturing and related activities.

There are around 4,000 companies operating in the textile sector in France.

The textile industry employs around 100,000 people in France.

Per capita consumption of textiles is around 9 to 10 kg per year.

These key figures show that the textile industry in France is diverse and dynamic, with significant opportunities in technical textiles, fashion and sustainable practices. The sector continues to evolve with a strong focus on innovation and sustainability to meet global challenges and consumer expectations.

Regulations

In France, the textile and clothing factories must comply with a number of strict regulations on air treatment to ensure worker safety and reduce environmental impact.

Factories must ensure regular monitoring of air quality, particularly for specific pollutants emitted by plastic manufacturing processes. This includes managing emissions of particles, vapours, and volatile organic compounds (VOCs), which can be toxic or contribute to air pollution.