Understanding your industry challenges

Paper and cardboard plants have to manage a number of constraints linked to comfort and air treatment to ensure efficient production while guaranteeing the health and safety of operators.

Air quality is a major concern because of the different types of pollutants generated by production processes.

- Paper dust

- Volatile organic compounds (VOCs)

- Gases and vapours such as sulphur dioxide (SO2) and chlorine.

Temperature management: The paper and cardboard manufacturing processes require specific temperatures to guarantee the quality of the finished product. Temperature variations can affect the quality of the paper, causing distortion or texture problems. Plants must therefore maintain a stable and appropriate temperature throughout the production process.

Humidity management: Relative air humidity plays a crucial role in paper manufacturing. Inappropriate humidity levels can cause problems such as paper curling or embrittlement. Plants use humidity control systems to maintain optimum levels, generally between 50% and 60%.

Air filtration and purification:

Paper dust and other particles can pose health risks to workers and affect machinery. Air filtration and dust removal systems are necessary to maintain a safe and clean working environment.

Ventilation: Adequate ventilation is essential to evacuate the vapours and dust produced during papermaking. It is important to renew the air and avoid the accumulation of harmful substances.

While paper and board mills face significant air quality challenges, they are implementing a variety of strategies and technologies to control and improve indoor air conditions and reduce the environmental impact of their operations.

It is also important to deal with the electrical rooms where the control and power management of the many electric motors that keep the processes running smoothly are located.

The high thermal load justifies specific air treatment similar to that found in Data Centres.

Papermakers will be paying particular attention to the presence of sulphur in the air and the high level of corrosion on copper. It was with this in mind that ETT opted for a specific design with passivated STAINLESS STEEL refrigeration circuits.

In addition to integrated heating and cooling via our thermodynamic system, it's possible to add supplementary equipment such as:

- Condensing gas modules

- Direct or indirect adiabatic coolers

- Chilled water, hot water, steam or CO2 coils

- Electric preheating, heating and auxiliary coils

Many industrial applications require ambient humidity regulation. This involves implementing equipment to dehumidify or humidify the air, such as:

- Thermodynamic or desiccant dehumidification

- Steam humidification with or without integrated production

Energy efficiency is a key concern for manufacturers. To this end, ETT can integrate various equipment and control features such as:

- Thermal wheels, plate heat exchangers, heat pipes, glycol coils

- Free cooling management

Managing air flow is essential for proper industrial process operation:

- Air turnover rate / homogenization of temperature and humidity conditions

- Fresh air compensation (process extraction)

- Positive or negative air pressure management

- High pressure air supply

Numerous constraints often require machines to be designed for integration into their environment. ETT's flexibility allows for:

- Custom dimensions and multi-block design

- Reinforced casing

- Anti-corrosion treatment of components and casing for harsh environments

- Aluminum or STAINLESS STEEL casing, paint finish

- Adaptation to acoustic constraints

Air quality is an important factor for operator comfort and production quality, requiring equipment for:

- Particle and molecular filtration

- Fresh air management

- ATEX (explosive atmosphere) risk management

- Recent regulatory developments, particularly the F-Gas regulation, strongly encourage the use of natural refrigerants.

- For several years, ETT has been incorporating Propane (R-290) as a refrigerant in various types of machines (air and water-based) such as:

- Air-to- Air heat pumps

- Chillers up to 1.2 MW

- Heat recovery chillers

- High temperature heat pumps up to 70°C

Special attention must be paid to equipment control to meet manufacturers' expectations. This is why ETT develops all of its algorithms to offer customized operation.

Additionally, the myETTvision supervision tool allows manufacturers to monitor their machines remotely and in real-time.

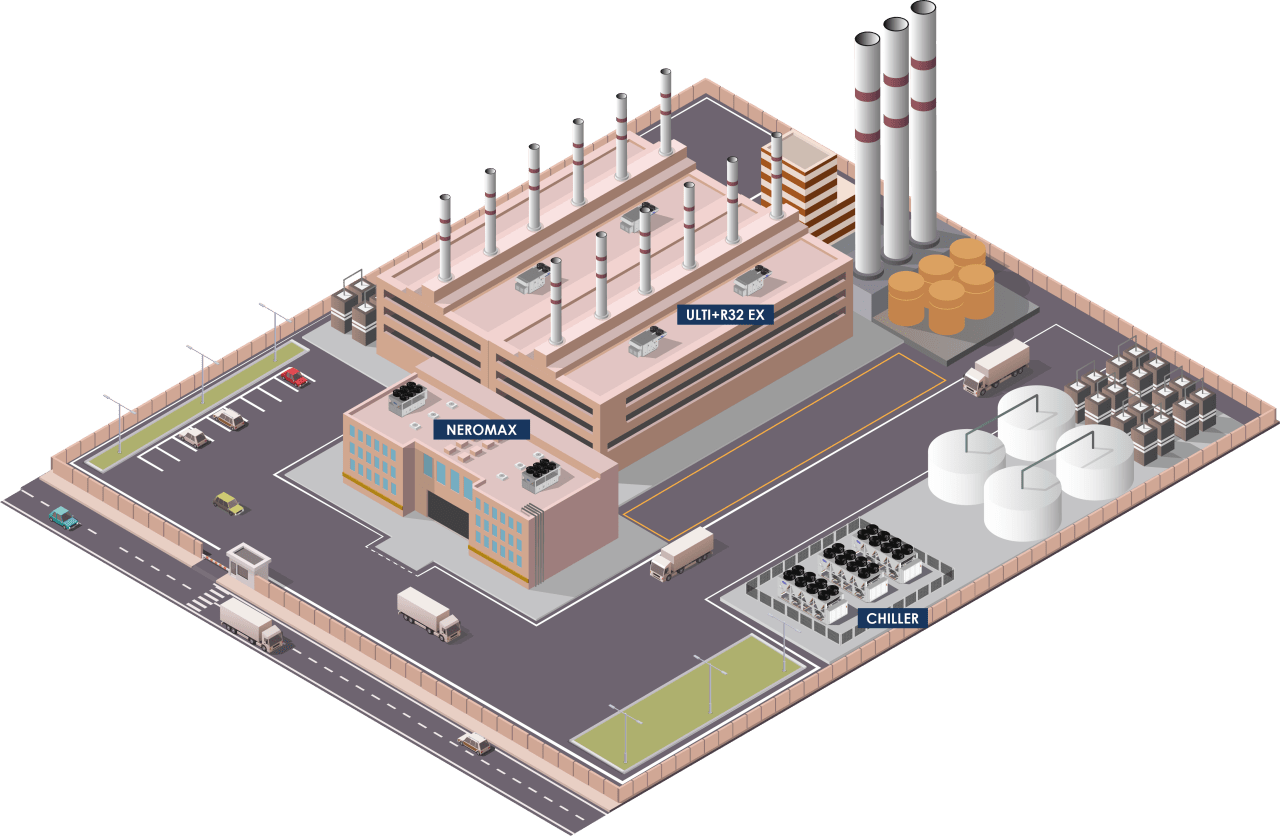

Your project

New build

Refurbishment

In pictures

Dedicated solutions

Have a question ?

A project ?

High-Performance and sustainable solutions for the Printing and Graphic Industry sector

The printing industry in France generated revenue of approximately 11 billion euros.

There are about 3,500 printing companies in France.

The sector employs nearly 60,000 people.

Regulations

In France, paper and cardboard mills must comply with a number of strict regulations on air treatment to ensure worker safety and reduce environmental impact. The main standards include the management of atmospheric emissions in accordance with European directives and national laws such as the Industrial Emissions Directive (IED) and the law on air and the rational use of energy.

Plants need to control and reduce emissions of dust, gases and volatile organic compounds (VOCs), which are often emitted during the paper and board manufacturing and converting processes. This requires the use of advanced filtration technologies and air treatment systems to ensure that emissions remain below defined legal thresholds.

In addition, companies must comply with requirements for continuous monitoring of emissions and the keeping of accurate records to demonstrate compliance. Regular inspections are carried out by the relevant authorities to ensure compliance with these strict environmental standards.

These regulations and initiatives are encouraging paper and board mills to adopt more sustainable practices, reducing their environmental impact while improving their operational efficiency.