Understanding your industry challenges

Plastics plants face a number of important energy issues, reflecting the challenges and opportunities in a context of energy transition and increased sustainability.

They use a lot of energy for transformation processes such as extrusion, injection moulding and thermoforming, which often require high temperatures and energy-intensive equipment.

Fluctuations in energy prices can have a significant impact on production costs, affecting their competitiveness on the market.

To meet the objectives of reducing CO2 emissions and reducing dependence on fossil fuels, players in this market are investing in highly energy-efficient technologies.

The machine tools used in plastics processing plants can generate significant amounts of heat as a result of the plastic transformation processes.

This implies a double management of cooling treatment:

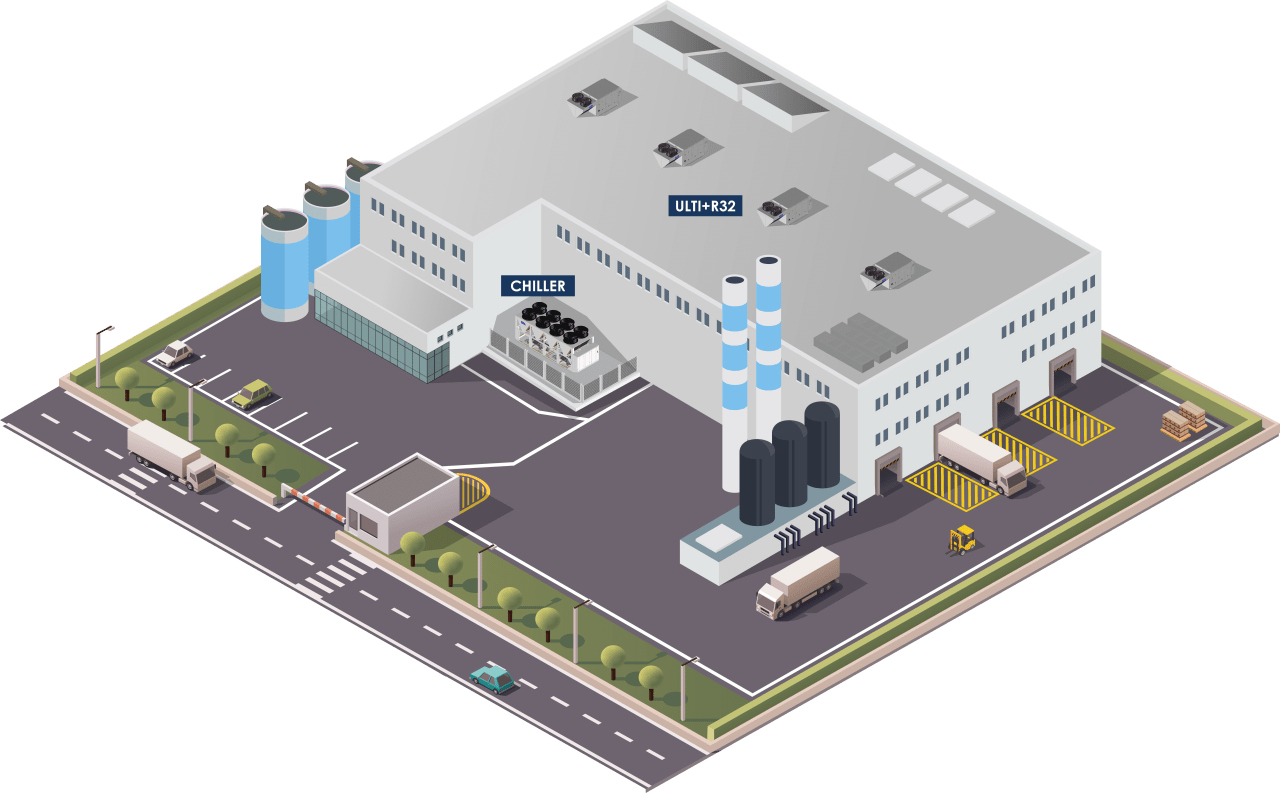

- Internal cooling of the machine tool: Cooled water production

- Ambient cooling: Air handling unit

Air treatment is also essential to ensure optimum working conditions that comply with health and safety standards. This involves controlling room temperature and humidity, managing indoor air quality and compensating for air loss, as opposed to extracting specific types of air.

In addition to integrated heating and cooling via our thermodynamic system, it's possible to add supplementary equipment such as:

- Condensing gas modules

- Direct or indirect adiabatic coolers

- Chilled water, hot water, steam or CO2 coils

- Electric preheating, heating and auxiliary coils

Many industrial applications require ambient humidity regulation. This involves implementing equipment to dehumidify or humidify the air, such as:

- Thermodynamic or desiccant dehumidification

- Steam humidification with or without integrated production

Energy efficiency is a key concern for manufacturers. To this end, ETT can integrate various equipment and control features such as:

- Thermal wheels, plate heat exchangers, heat pipes, glycol coils

- Free cooling management

Managing air flow is essential for proper industrial process operation:

- Air turnover rate / homogenization of temperature and humidity conditions

- Fresh air compensation (process extraction)

- Positive or negative air pressure management

- High pressure air supply

Numerous constraints often require machines to be designed for integration into their environment. ETT's flexibility allows for:

- Custom dimensions and multi-block design

- Reinforced casing

- Anti-corrosion treatment of components and casing for harsh environments

- Aluminum or STAINLESS STEEL casing, paint finish

- Adaptation to acoustic constraints

Air quality is an important factor for operator comfort and production quality, requiring equipment for:

- Particle and molecular filtration

- Fresh air management

- ATEX (explosive atmosphere) risk management

Recent regulatory developments, particularly the F-Gas regulation, strongly encourage the use of natural refrigerants.

For several years, ETT has been incorporating Propane (R-290) as a refrigerant in various types of machines (air and water-based) such as:

- Air-to- Air heat pumps

- Chillers up to 1.2 MW

- Heat recovery chillers

- High temperature heat pumps up to 70°C

Special attention must be paid to equipment control to meet manufacturers' expectations. This is why ETT develops all of its algorithms to offer customized operation.

Additionally, the myETTvision supervision tool allows manufacturers to monitor their machines remotely and in real-time.

Your project ?

New build

Refurbishment

In pictures

Dedicated solutions

Have a question ?

A project ?

High-performance and sustainable solutions for the plastics industry

The plastics industry in France is a major sector, with a number of key figures illustrating its economic weight and impact on the country. Here are some recent figures:

Some 4,300 companies operate in the plastics sector in France.

The plastics industry employs around 100,000 people in France, covering both the production of plastics and the conversion of plastic materials.

The French plastics industry generates annual sales of around €30 billion.

Annual plastics production in France is around 7.5 million tonnes.

Around 70% of French plastics production is exported to other countries, demonstrating the importance of exports to the sector.

Regulations

In France, plastics industry must comply with a number of strict regulations on air treatment to ensure worker safety and reduce environmental impact.

Factories must ensure regular monitoring of air quality, particularly for specific pollutants emitted by plastic manufacturing processes. This includes managing emissions of particles, vapours, and volatile organic compounds (VOCs), which can be toxic or contribute to air pollution.