Understanding your industry challenges

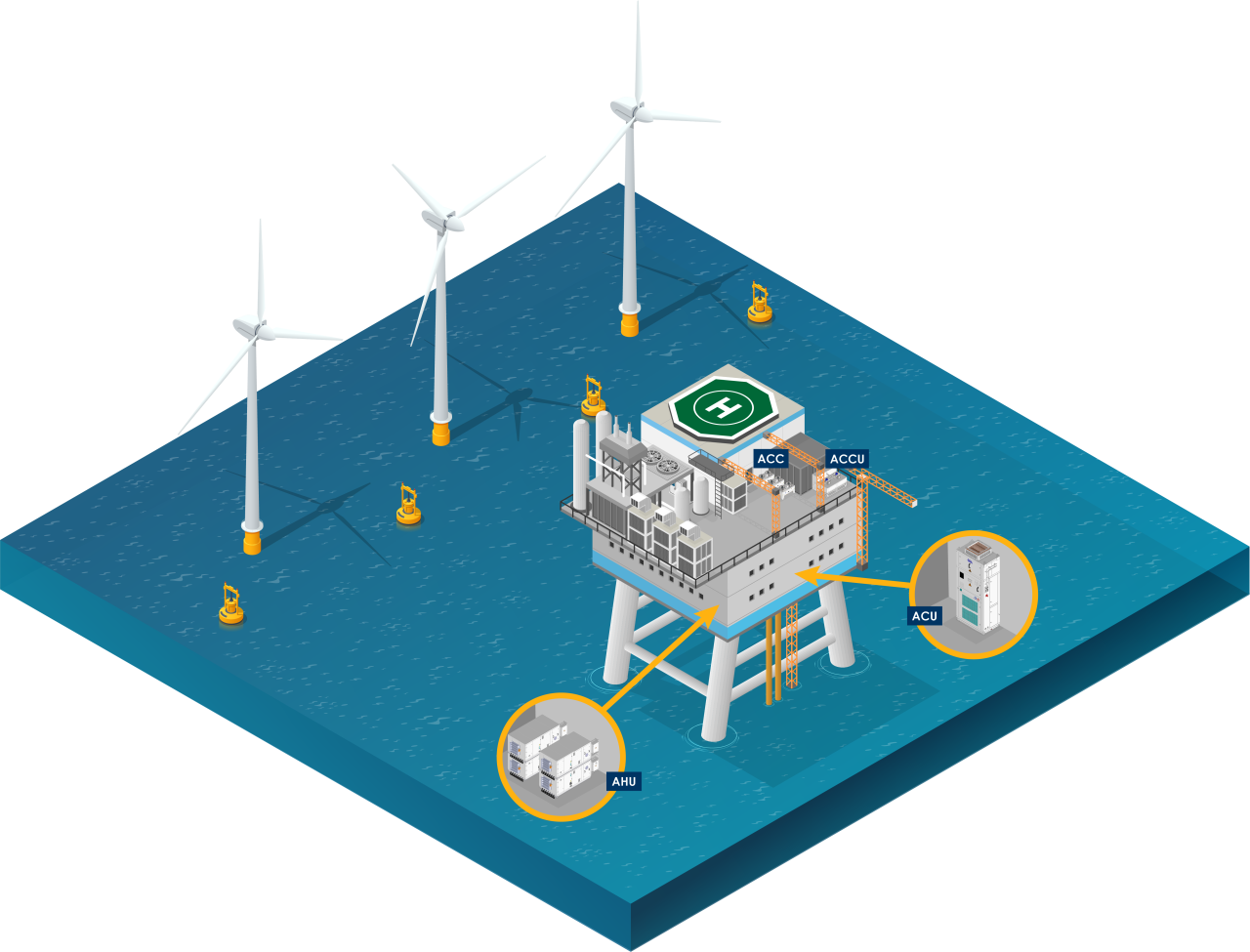

Our machines are designed to withstand corrosive marine environments. Various types of materials and options are available to meet these requirements.

As these platforms are unmanned and offshore interventions extremely costly, the design and selection of components require high reliability, minimal maintenance, and long service life.

ETT has positioned itself as a major player in this market, recognised by various energy companies and EPC (Engineering, Procurement and Construction) contractors.

With its extensive range of equipment, ETT is able to offer both standardised and bespoke solutions tailored to the specific requirements and constraints of each client, whether for new installations or for revamping existing systems. Our equipment is engineered with a focus on ease of maintenance, reparability, robustness, and sustained performance, even in highly corrosive environments.

The various processes on offshore wind platforms are subject to stringent comfort and air treatment requirements to ensure optimal operation and operator safety. Maintaining a constant temperature is essential to prevent fluctuations that could impact sensitive equipment.

To address these unique site constraints, ETT can provide a fully autonomous, integrated air handling solution encompassing all the functionalities required for managing your industrial environment.

In addition to the on-board production of heating or cooling via our thermodynamic system, it is possible to add additional equipment such as:

Chilled water, hot water, coils,

Electric pre-heating, heating or auxiliary equipment

Many industrial applications require regulation of ambient humidity levels. This involves the implementation of equipment that allows for air dehumidification, such as:

Thermodynamic dehumidification,

Electric auxiliary dehumidification,

Desiccant dehumidification

Energy efficiency is a key concern for industrial operators in sectors such as Marine Renewable Energy (MRE), where the objective is to generate electricity, not to consume it through auxiliary systems. To this end, ETT can integrate various equipment and control features such as:

Heat recovery wheels, plate heat exchangers, heat pipes, glycol water coils

Free cooling management

Through its Energy Performance department, ETT is able to compare various technical solutions to assess CAPEX over several years.

Many constraints often require machines to be designed to fit into their environment. ETT's flexibility allows for:

Custom dimensions and multi-block design

Reinforced casings

Anti-corrosion treatment for components and casing for aggressive environments

Marine-grade aluminium or stainless steel casings,

Specific coatings

Custom dimensions to match existing installations for revamping projects

Managing air flow is essential for proper industrial process operation:

Air mixing / homogenisation of temperature and humidity conditions

Fresh air compensation (extraction process)

Positive or negative air pressure management

High-pressure air supply

Air quality is an important factor for operator comfort and production quality, requiring equipment for:

Particulate and molecular filtration

Fresh air management

ATEX (explosive atmosphere) risk management

Recent regulatory developments, particularly the F-Gas regulation, strongly encourage the use of natural refrigerants:

Air-to-air heat pump

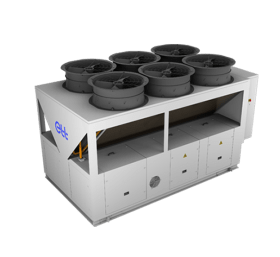

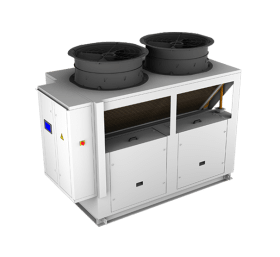

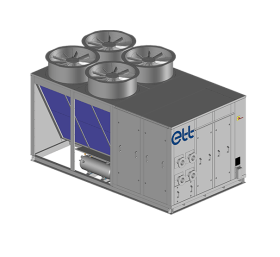

Chillers up to 1.2 MW

Heat recovery chillers

High-temperature heat pumps up to 70°C

If this refrigerant cannot be used for safety reasons, ETT can offer alternatives such as R513A or R32.

.

Special attention must be paid to equipment control systems to meet the expectations of industrial clients. That is why ETT develops all of its algorithms to offer customized operation.

Additionally, the myETTvision supervision tool allows industrial clients to monitor their machines remotely and in real-time.

A range of options with various types of displays (touchscreen or not) to facilitate maintenance of installations.

A dedicated MRE team within the Energy and Marine Markets department

A project manager assigned to your requirements

Compliance check list in accordance with client’s specifications

Detailed 2D and 3D drawings

Recommendations for system interfaces

Test and inspection plans for units and components

Material certificates (2.1, 2.2, 3.1)

Sensor calibration certificates

Welding log books

Schedules (Purchase Orders, production, etc.)

Other documentation as required

Layout of pipes and ducts

Your project

New build

Refurbishment

In pictures...

Dedicated solutions

Have a question?

A project?

A strong expertise in the field of Marine Renewable Energy (MRE), at the core of our capabilities

The MRE industry remains very active across various continents, both in the development of new projects and in the upgrading or revamping of existing installations to ensure compliance.

Present in various countries with diverse climatic conditions, from the North Sea to the South China Sea, ETT is recognised by leading energy companies and EPCs as a supplier of reliable and durable equipment.

ETT’s proven expertise enables us to respond to a wide range of requirements for different types of equipment.

.

Regulations

ETT equipment meets the most demanding specifications of major industry players and is vendor-listed with many energy companies.

Our products comply with refrigeration equipment standards (EN 378) and ISO 15138 for HVAC system design on offshore platforms.