Understanding your industry challenges

In the woodworking and joinery industry, the constraints of comfort and air treatment are crucial to ensuring the health and safety of workers, as well as maintaining product quality.

Indoor air quality is a major concern, as wood or aluminium dust can cause serious respiratory problems, skin irritations and allergies.

General ventilation systems are needed to renew the air, dilute the contaminants present in the ambient air and ensure even distribution of the air in the workshops.

Effective systems are therefore needed to remove these VOCs and maintain acceptable air quality. Glues, varnishes and other chemical products used in joinery emit VOCs and can be harmful to health. HEPA filters are strongly recommended to capture fine particles. Other technologies are available, such as UV purifiers to remove contaminants from the air.

For workshops equipped with localised extraction systems to capture dust at source, an air compensation system will have to be set up with an appropriate heat treatment.

Heating and cooling requirements can vary according to season and activity.

Only wood-drying processes require a controlled temperature.

Moisture levels must be controlled to avoid warping and cracking of the wood. Excessively high humidity levels can also promote the growth of molds and fungi. Dehumidification can be used to maintain optimum humidity levels.

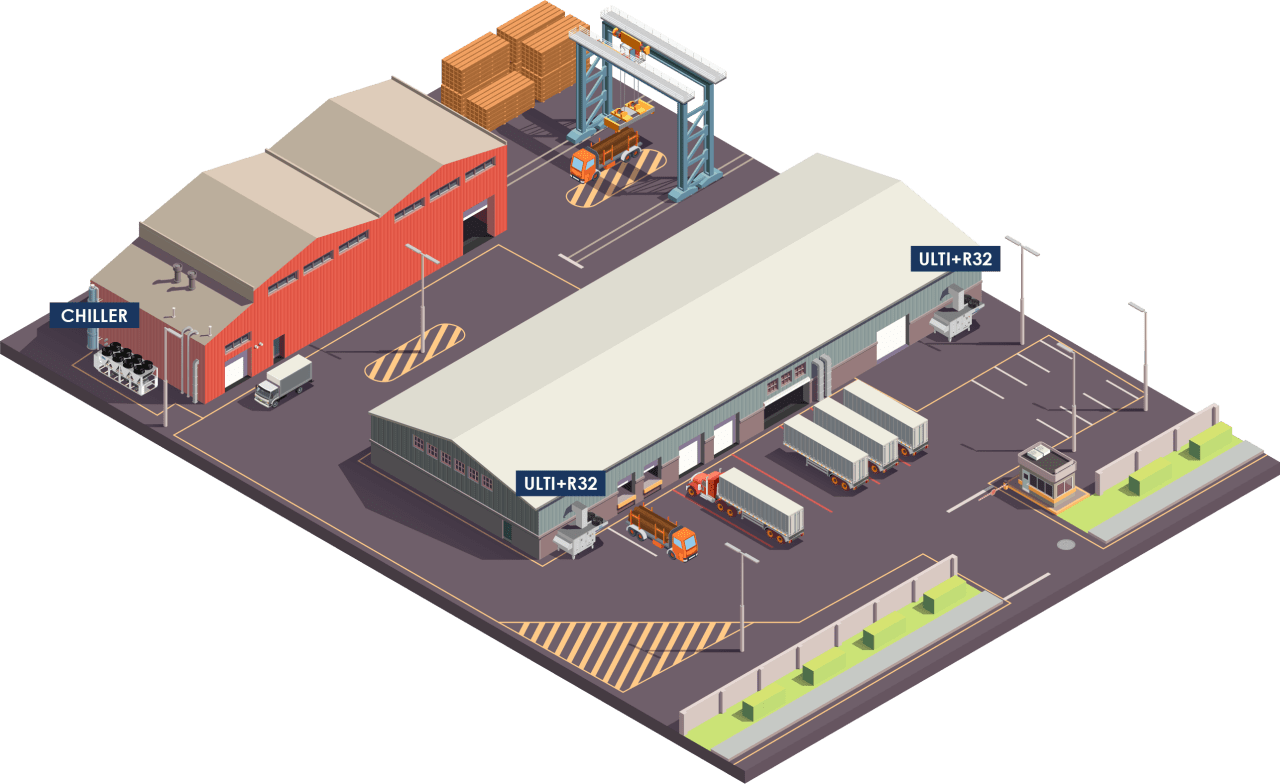

In addition to integrated heating and cooling via our thermodynamic system, it's possible to add supplementary equipment such as:

- Condensing gas modules

- Direct or indirect adiabatic coolers

- Chilled water, hot water, steam or CO2 coils

- Electric preheating, heating and auxiliary coils

Many industrial applications require ambient humidity regulation. This involves implementing equipment to dehumidify or humidify the air, such as:

Thermodynamic or desiccant dehumidification

Steam humidification with or without integrated production

Energy efficiency is a key concern for manufacturers. To this end, ETT can integrate various equipment and control features such as:

- Thermal wheel, plate heat exchanger, heat pipe, glycol coils

- Free cooling management

Managing air flow is essential for proper industrial process operation:

- Air turnover rate / homogenization of temperature and humidity conditions

- Fresh air compensation (process extraction)

- Positive or negative air pressure management

- High pressure air supply

Numerous constraints often require machines to be designed for integration into their environment. ETT's flexibility allows for:

- Custom dimensions and multi-block design

- Reinforced casing

- Anti-corrosion treatment of components and casing for harsh environments

- Aluminum or STAINLESS STEEL casing, paint finish

- Adaptation to acoustic constraints

Air quality is an important factor for operator comfort and production quality, requiring equipment for:

- Particule and molecular filtration

- Fresh air management

- ATEX (explosive atmosphere) risk management

Recent regulatory developments, particularly the F-Gas regulation, strongly encourage the use of natural refrigerants.

For several years, ETT has been incorporating Propane (R-290) as a refrigerant in various types of machines (air and water-based) such as:

- Air-to- Air heat pump

- Chillers up to 1.2 MW

- Heat recovery chillers

- High temperature heat pumps up to 70°C

Special attention must be paid to equipment control to meet manufacturers' expectations. This is why ETT develops all of its algorithms to offer customized operation.

Additionally, the myETTvision supervision tool allows manufacturers to monitor their machines remotely and in real-time.

Your project?

New build

Refurbishment

In pictures...

Dedicated solutions

Have a question?

A project?

High-Performance and Sustainable Solutions for the Wood and Joinery Industry

France has around 17 million hectares of forest, representing almost 31% of the country's land area.

Around 70 million cubic metres of wood are harvested every year.

The wood and joinery sector generates sales of around €60 billion a year.

The sector accounts for around 2% of France's GDP.

The wood and joinery industry employs around 540,000 people.

There are around 80,000 companies in the wood industry, the vast majority of which are small and medium-sized enterprises (SMEs).

The craft joinery sector is particularly dynamic, with a strong presence on the local market.

Regulations

Air treatment in joinery factories is governed by a number of regulations designed to ensure the safety of workers and the protection of the environment. The European ATEX (Explosive Atmospheres) directive imposes preventive measures against the risk of explosion caused by wood dust. Installations must be equipped with effective extraction and filtration systems to limit concentrations of flammable dust.

The French Labour Code (articles R4222-1 to R4222-17) stipulates that the air in work premises must be renewed and maintained at a satisfactory quality. Ventilation systems must remove pollutants at source and guarantee an adequate air flow.

Installations classified for environmental protection (ICPE) under headings 1530 and 1532 impose specific standards for the discharge and treatment of atmospheric emissions. Companies must carry out regular checks and comply with the discharge thresholds defined by the prefectoral decree.