Understanding your industry challenges

Food processing plants must meet stringent air quality and comfort requirements while also addressing specific and substantial needs for chilled and hot water production for various production, preservation, and hygiene processes.

In this context, ETT develops innovative and customized solutions for both air treatment and water production.

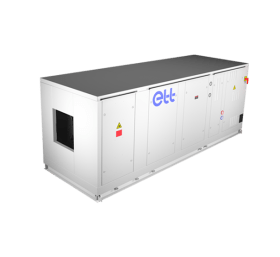

Self-contained air handling units:

- Thermodynamic air handling units operating on outdoor or extracted air

- These units maintain optimal temperatures in production and storage areas while ensuring constant air renewal to eliminate contaminants and maintain a clean environment.

- They integrate HEPA filters or other advanced filtration technologies to remove particles, bacteria, and other air pollutants.

- The systems can incorporate dehumidification functions to prevent condensation and mold growth.

- Energy recovery from processes is utilized to enhance system efficiency.

- Custom designs are available to adapt to dimensional or acoustic constraints

- Automated coil cleaning systems are integrated

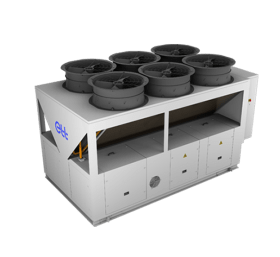

Chilled water production:

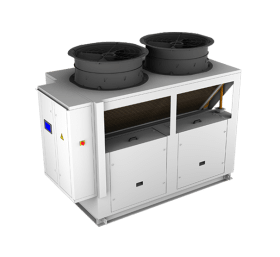

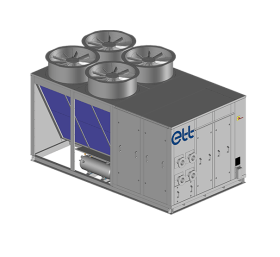

- Air-to-water thermodynamic production units

- Process cooling for rapid product chilling, or low-temperature storage

- These systems capitalize on free heat recovery.

- Natural refrigerant (Propane - R290) to address environmental concerns

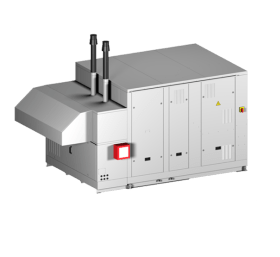

Hot water production:

- Air-to-water thermodynamic production units

- Preheating or heating of water for processing and domestic hot water

- Natural refrigerant (Propane - R290) to address environmental concerns

In addition to integrated heating and cooling via our thermodynamic system, it's possible to add supplementary equipment such as:

Condensing gas module

Direct or indirect adiabatic cooler

Chilled water, hot water, steam or CO2 coil

Electric preheating, heating and auxiliary coil

Many industrial applications require ambient humidity regulation. This involves implementing equipment to dehumidify or humidify the air, such as:

Thermodynamic or desiccant dehumidification

Steam humidification with or without integrated production

Energy efficiency is a key concern for manufacturers. To this end, ETT can integrate various equipment and control features such as:

Thermal wheel, plate heat exchanger, heat pipe, glycol coils

Free cooling management

Managing air flow is essential for proper industrial process operation:

Air turnover rate / homogenization of temperature and humidity conditions

Fresh air compensation (process extraction)

Positive or negative air pressure management

High pressure air supply

Numerous constraints often require machines to be designed for integration into their environment. ETT's flexibility allows for:

Custom dimensions and multi-block design

Reinforced casing

Anti-corrosion treatment of components and casing for harsh environments

Aluminum or stainless steel casing, paint finish

Adaptation to acoustic constraints

Air quality is an important factor for operator comfort and production quality, requiring equipment for:

Particule and molecular filtration

Fresh air management

ATEX (explosive atmosphere) risk management

Recent regulatory developments, particularly the F-Gas regulation, strongly encourage the use of natural refrigerants.

For several years, ETT has been incorporating Propane (R-290) as a refrigerant in various types of machines (air and water-based) such as:

Air-to-air heat pumps

Chillers up to 1.2 MW

Heat recovery chillers

High temperature heat pumps up to 70°C

Special attention must be paid to equipment control to meet manufacturers' expectations. This is why ETT develops all of its algorithms to offer customized operation.

Additionally, the myETTvision supervision tool allows manufacturers to monitor their machines remotely and in real-time.

Your project

New build

Refurbishment

Have a question ?

A project ?

Strong expertise in the food industry, at the heart of our skills

The French food industry generates an annual turnover of over 180 billion euros, making it one of the most significant sectors in the French economy.

The sector comprises approximately 17,000 companies, with a majority being small and medium-sized enterprises (SMEs).

The food industry employs nearly 430,000 people, representing about 20% of industrial employment in France, making it the country's leading industrial employer.

Regulations

Food processing plants must navigate a complex regulatory framework to ensure compliance and optimize energy consumption. Collaboration with energy and environmental experts is often necessary to comply with all legal requirements and take advantage of energy-saving opportunities.

Regulations on air treatment in food processing plants are stringent to ensure product safety and quality. Key standards include compliance with Good Hygiene Practices (GHP) and food safety in accordance with HACCP (Hazard Analysis Critical Control Point) principles. Air must be filtered to remove contaminants, with HEPA filters often required in sensitive areas.

Regulation (EC) No. 852/2004 on food hygiene requires premises to be designed to prevent cross-contamination. Ventilation systems must be properly maintained and regularly checked to prevent the spread of microorganisms.

These regulations aim to ensure a safe and clean environment, essential for food production without risk of contamination.

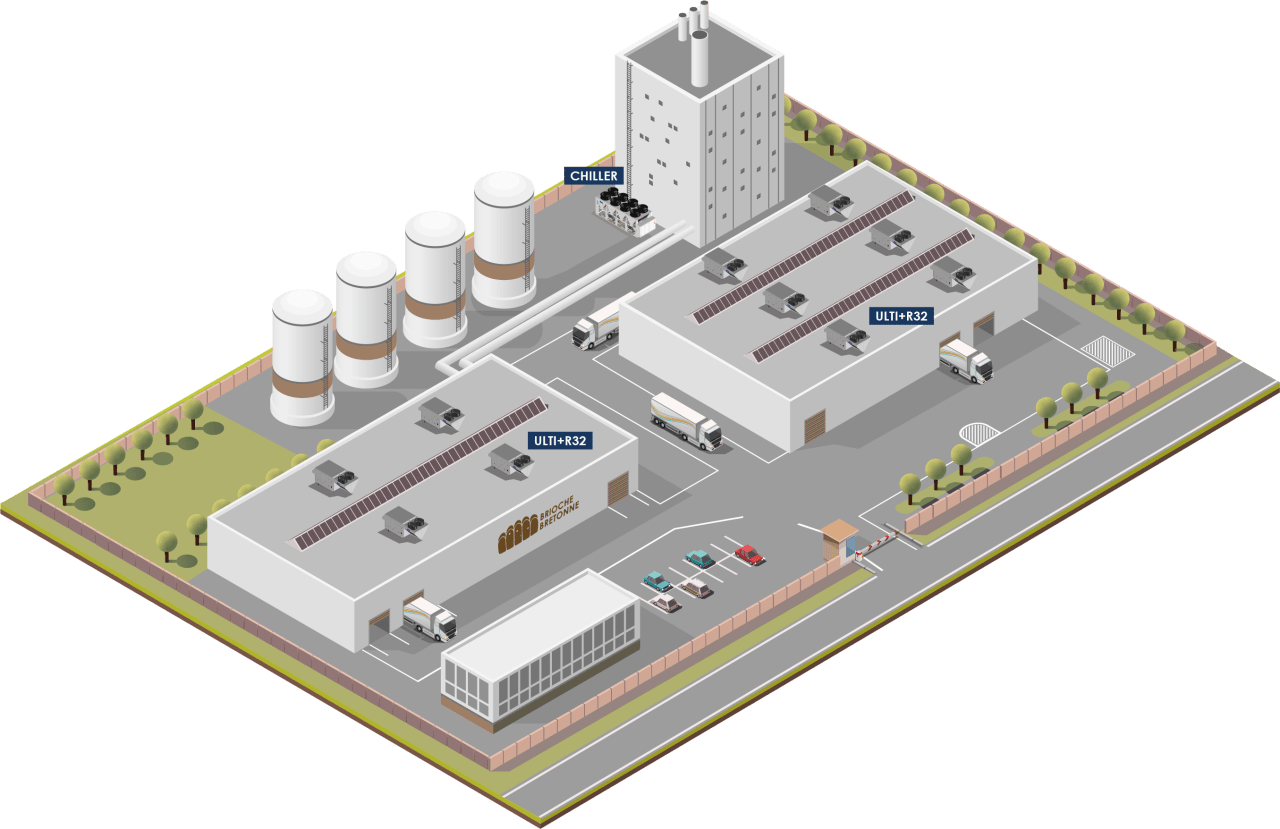

In pictures...