Understanding your industry challenges

In sorting centres or water treatment plants, managing comfort and air treatment requires an integrated approach, taking into account the needs of employees and operational requirements to ensure an optimum working environment.

Maintain an adequate room temperature for employee comfort, often between 18°C and 24°C.

The ventilation system will be specially designed to prevent the accumulation of pollutants and to ensure constant air renewal.

Ventilation units are generally designed to work with fresh air, and installing an energy recovery coil can significantly reduce the system's overall energy consumption.

In addition to integrated heating and cooling via our thermodynamic system, it's possible to add supplementary equipment such as:

- Condensing gas modules

- Direct or indirect adiabatic coolers

- Chilled water, hot water, steam or CO2 coils

- Electric preheating, heating and auxiliary coils

Many industrial applications require ambient humidity regulation. This involves implementing equipment to dehumidify or humidify the air, such as:

- Thermodynamic or desiccant dehumidification

- Steam humidification with or without integrated production

Energy efficiency is a key concern for manufacturers. To this end, ETT can integrate various equipment and control features such as:

- Thermal wheels, plate heat exchangers, heat pipes, glycol coils

- Free cooling management

Managing air flow is essential for proper industrial process operation:

- Air turnover rate / homogenization of temperature and humidity conditions

- Fresh air compensation (process extraction)

- Positive or negative air pressure management

- High pressure air supply

Numerous constraints often require machines to be designed for integration into their environment. ETT's flexibility allows for:

- Custom dimensions and multi-block design

- Reinforced casing

- Anti-corrosion treatment of components and casing for harsh environments

- Aluminum or STAINLESS STEEL casing, paint finish

- Adaptation to acoustic constraints

Air quality is an important factor for operator comfort and production quality, requiring equipment for:

- Particle and molecular filtration

- Fresh air management

- ATEX (explosive atmosphere) risk management

Recent regulatory developments, particularly the F-Gas regulation, strongly encourage the use of natural refrigerants.

For several years, ETT has been incorporating Propane (R-290) as a refrigerant in various types of machines (air and water-based) such as:

- Air-to- Air heat pumps

- Chillers up to 1.2 MW

- Heat recovery chillers

- High temperature heat pumps up to 70°C

Special attention must be paid to equipment control to meet manufacturers' expectations. This is why ETT develops all of its algorithms to offer customized operation.

Additionally, the myETTvision supervision tool allows manufacturers to monitor their machines remotely and in real-time.

Your project

New build

Refurbishment

In pictures

Dedicated solutions

Have a question?

A project?

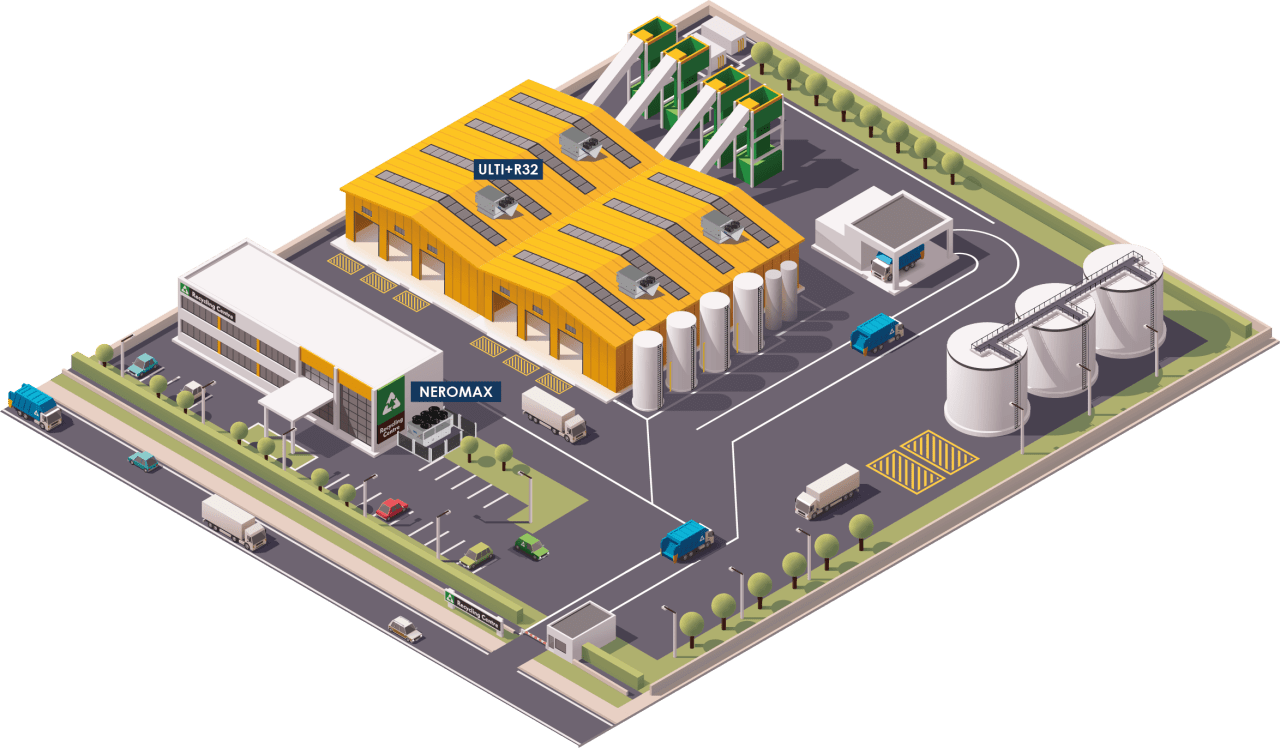

High-performance, sustainable solutions for the Energy and Environment sectors

60 million tonnes of waste collected each year, with a significant proportion destined for sorting.

Around 43% of municipal waste recycled by 2022, with a target of 65% by 2030.

Around 200 sorting centres in France, including facilities for household, industrial and recyclable waste.

Around €1.5 to 2 billion invested in the sorting and recycling sector every year.

The sector generates around 40,000 direct jobs, with an upward trend due to the increasing volumes of waste to be processed.

The sorting centre sector in France is expanding rapidly, driven by sustainability objectives and increasingly stringent regulations. Investment and technological innovation are key to meeting these challenges.

Regulations

It is essential for sorting centres and wastewater treatment plants to comply with these standards to ensure not only legal compliance, but also the safety and comfort of employees, while guaranteeing the efficiency of the facilities.

Air treatment is governed by a number of regulations designed to protect public health and the environment.

This includes requirements for ventilation, dust control and odour management. Specific devices such as filtration, dust removal and VOC (volatile organic compound) treatment systems are often required. Centres must also carry out regular checks and provide compliance reports to the competent authorities.