Understanding your industry challenges

Manufacturing processes for electronic and electrical components have to meet strict comfort and air treatment requirements to guarantee product quality and operator safety.

Maintaining a constant temperature is crucial to avoid variations that could affect manufacturing processes and product quality. This must be in line with the comfort of employees to ensure their well-being and productivity.

Controlling humidity is essential to avoid any variations that could cause electrostatic discharges (ESD), which are harmful to sensitive electronic components. An optimum level of relative humidity must be maintained to minimise these risks.

The manufacture of electronic components, particularly semi-conductors, requires ultra-clean environments. Cleanrooms must be classified according to specific standards to control the concentration of airborne particles. Ventilation systems must be designed to minimise cross-contamination by using HEPA or ULPA filters to eliminate fine particles (ePM1 and ePM2.5).

Manufacturing processes can generate toxic gases and vapours that need to be captured and treated by appropriate ventilation and filtration systems. This quantity of exhaust air will have to be compensated for by fresh outside air, which will have to be thermally treated.

In cleanrooms, positive pressurisation is often maintained to prevent the entry of external contaminants.

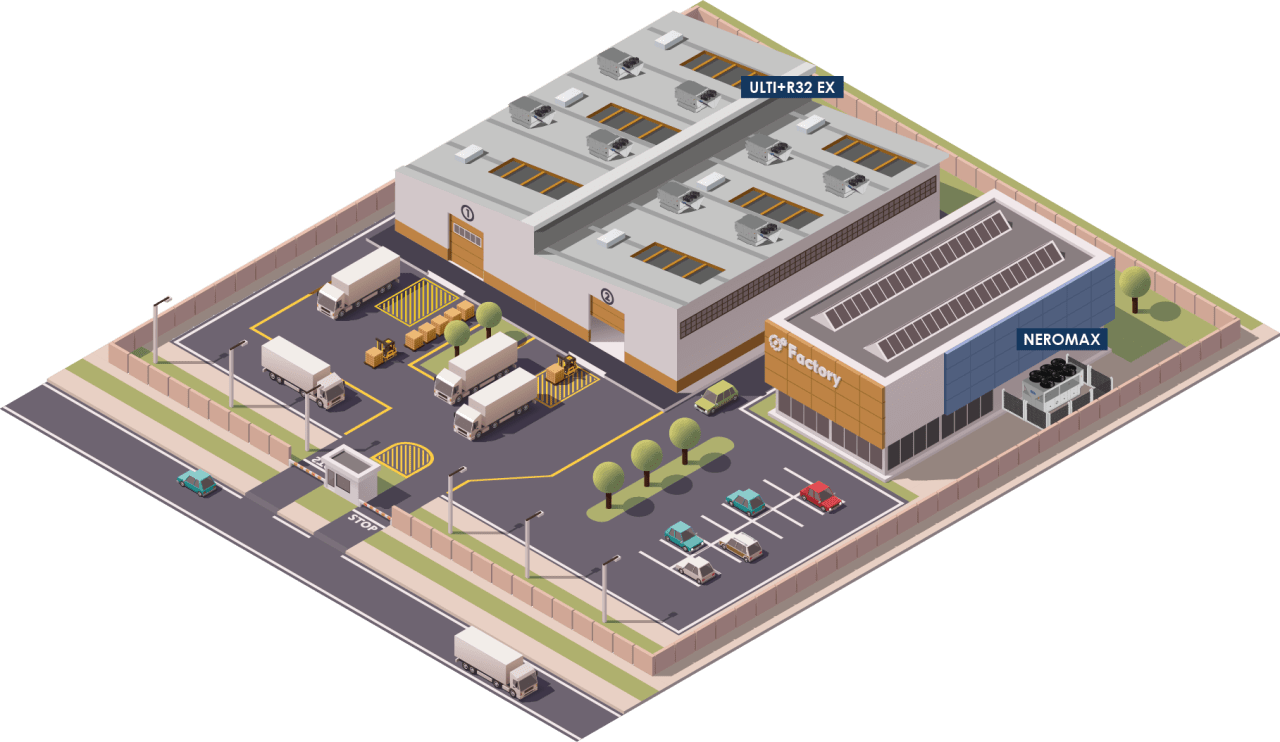

To meet all these requirements, ETT can provide you with a stand-alone global air handling solution incorporating all the functions needed to manage your industrial environment.

In addition to integrated heating and cooling via our thermodynamic system, it's possible to add supplementary equipment such as:

- Condensing gas modules

- Direct or indirect adiabatic coolers

- Chilled water, hot water, steam or CO2 coils

- Electric preheating, heating and auxiliary coils

Many industrial applications require ambient humidity regulation. This involves implementing equipment to dehumidify or humidify the air, such as:

- Thermodynamic or desiccant dehumidification

- Steam humidification with or without integrated production

Energy efficiency is a key concern for manufacturers. To this end, ETT can integrate various equipment and control features such as:

- Thermal wheels, plate heat exchangers, heat pipes, glycol coils

- Free cooling management

Managing air flow is essential for proper industrial process operation:

- Air turnover rate / homogenization of temperature and humidity conditions

- Fresh air compensation (process extraction)

- Positive or negative air pressure management

- High pressure air supply

Numerous constraints often require machines to be designed for integration into their environment. ETT's flexibility allows for:

- Custom dimensions and multi-block design

- Reinforced casing

- Anti-corrosion treatment of components and casing for harsh environments

- Aluminum or STAINLESS STEEL casing, paint finish

- Adaptation to acoustic constraints

Air quality is an important factor for operator comfort and production quality, requiring equipment for:

- Particle and molecular filtration

- Fresh air management

- ATEX (explosive atmosphere) risk management

Recent regulatory developments, particularly the F-Gas regulation, strongly encourage the use of natural refrigerants.

For several years, ETT has been incorporating Propane (R-290) as a refrigerant in various types of machines (air and water-based) such as:

- Air-to- Air heat pumps

- Chillers up to 1.2 MW

- Heat recovery chillers

- High temperature heat pumps up to 70°C

Special attention must be paid to equipment control to meet manufacturers' expectations. This is why ETT develops all of its algorithms to offer customized operation.

Additionally, the myETTvision supervision tool allows manufacturers to monitor their machines remotely and in real-time.

Your project

New build

Refurbishment

In pictures

Dedicated solutions

Have a question?

A project?

High-performance, sustainable solutions for the electrical and electronics industries

The sector is made up of a multitude of SMEs as well as large companies. Around 200 key companies are active in the manufacture and distribution of electrical and electronic components in France.

In France, the production of electronic and electrical components is a major pillar of the economy. The sector currently employs around 100,000 people

Regulations

In France, regulations on air treatment in factories producing electronic and electrical components are strict in order to guarantee product quality and worker safety. The main standards include:

- ISO 14644: This international standard governs cleanrooms and specifies classes of air cleanliness based on the number of particles per cubic metre.

- REACH regulations (Registration, Evaluation, Authorisation and Restriction of Chemicals): Imposing restrictions on the use of chemical substances that are potentially hazardous to health and the environment.

These regulations aim to reduce the environmental impact of plants producing electronic and electrical components, while improving energy efficiency and guaranteeing a safe and healthy working environment. Companies must put in place appropriate management systems and invest in advanced technologies to comply with these requirements.