Understanding your industry challenges

The energy requirements of defence and armaments plants are considerable and complex, due to the nature of their production, research and development activities.

The manufacture of military equipment, such as fighter aircraft, warships and defence systems, requires large amounts of energy, particularly for metallurgy, precision machining and testing.

Facilities must ensure the security of the energy supply to avoid the risk of espionage or sabotage, which may include redundant energy sources.

There is a strong focus on the treatment of industrial environments to guarantee safety, product quality and employee well-being.

They regulate temperature, humidity and air quality to keep the air clean and safe. It is also advisable to manage excess air pressure to prevent any external pollution from entering.

Production environments must be free from contaminants to avoid defects in sensitive products, such as military electronics. Clean rooms or controlled production areas may be required.

Systems can include energy recovery devices to minimise energy and environmental impact.

Reliability is also an essential criterion in equipment design. The integration of premium components makes ETT a first-rate supplier.

In addition to integrated heating and cooling via our thermodynamic system, it's possible to add supplementary equipment such as:

- Condensing gas modules

- Direct or indirect adiabatic coolers

- Chilled water, hot water, steam or CO2 coils

- Electric preheating, heating and auxiliary coils

Many industrial applications require ambient humidity regulation. This involves implementing equipment to dehumidify or humidify the air, such as:

- Thermodynamic or desiccant dehumidification

- Steam humidification with or without integrated production

Energy efficiency is a key concern for manufacturers. To this end, ETT can integrate various equipment and control features such as:

- Thermal wheel, plate heat exchanger, heat pipe, glycol coils

- Free Cooling management

Managing air flow is essential for proper industrial process operation:

- Air turnover rate / homogenization of temperature and humidity conditions

- Fresh air compensation (process extraction)

- Positive or negative air pressure management

- High pressure air supply

Numerous constraints often require machines to be designed for integration into their environment. ETT's flexibility allows for:

- Custom dimensions and multi-block design

- Reinforced casing

- Anti-corrosion treatment of components and casing for harsh environments

- Aluminum or STAINLESS STEEL casing, paint finish

- Adaptation to acoustic constraints

Air quality is an important factor for operator comfort and production quality, requiring equipment for:

- Particle and molecular filtration

- Fresh air management

- ATEX (explosive atmosphere) risk management

Recent regulatory developments, particularly the F-Gas regulation, strongly encourage the use of natural refrigerants.

For several years, ETT has been incorporating Propane (R-290) as a refrigerant in various types of machines (air and water-based) such as:

- Air-to- Air heat pumps

- Chillers up to 1.2 MW

- Heat recovery chillers

- High temperature heat pumps up to 70°C

Special attention must be paid to equipment control to meet manufacturers' expectations. This is why ETT develops all of its algorithms to offer customized operation..

Additionally, the myETTvision supervision tool allows manufacturers to monitor their machines remotely and in real-time.

Your project?

New build

Refurbishment

In pictures

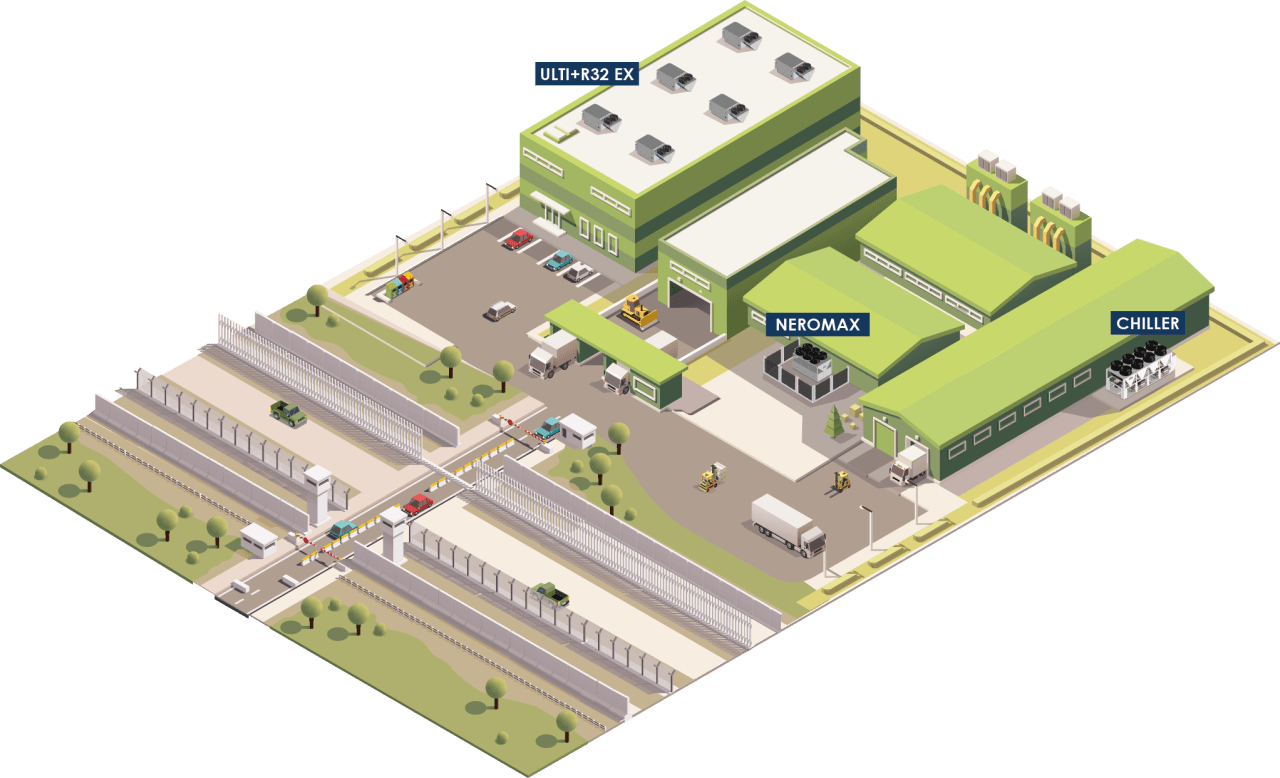

Dedicated solutions

Have a question?

A project ?

High-performance and Sustainable solutions for the Defence and Armaments Sector

The defence and armaments industry plays a crucial role, both economically and strategically, and must adapt to geopolitical and technological developments.

In 2024, France will devote more than 2% of its GDP to defence spending, amounting to around €50 billion.

France is the world's third largest exporter of defence equipment.

The defence industry directly employs around 200,000 people in France, with thousands more jobs indirectly linked to the sector through subcontractors and partner SMEs.

Regulations

Like other industrial markets, the Defence and Armaments markets are governed by a number of directives and standards aimed at reducing environmental impact and improving energy efficiency.

- European Directive on Industrial Emissions (IED): This directive imposes measures to prevent and reduce air pollution from industrial installations.

- Standards specific to the defence industry: Specific rules may apply, in particular for substances used in the manufacture of weapons and ammunition.

- Risk management plan: Plants must develop and implement risk management plans to prevent and control accidental or uncontrolled emissions.

These regulations aim to ensure safe production while minimising environmental impact.

France is committed to decarbonising its energy mix, in particular by increasing the production and consumption of decarbonised electricity. The targets are set out in the French Multiannual Energy Programme (PPE), which stipulates, for example, that 40% of electricity should be generated by renewable energies by 2030.