Understanding your industry challenges

Data centres consume large amounts of electricity to power servers and other IT equipment. In 2022, they represented approximately 2% of the total electricity consumption in France.

A significant proportion of energy (55%) is dedicated to cooling equipment to maintain optimum operating temperatures and avoid overheating.

Energy efficiency is therefore at the heart of the drive to cut costs and reduce our carbon footprint. Power Usage Effectiveness (PUE) is a key indicator for measuring this efficiency.

These needs and constraints are forcing data centre operators to constantly innovate in order to improve their energy efficiency and minimise their environmental impact.

ETT works with data centre designers to develop innovative, highly efficient systems.

Room temperature management can sometimes be combined with water weight management. The recommended temperature range is generally between 18°C and 27°C. Efficient cooling systems are therefore crucial. When it comes to indoor humidity, a setting of between 40% and 60% is often required.

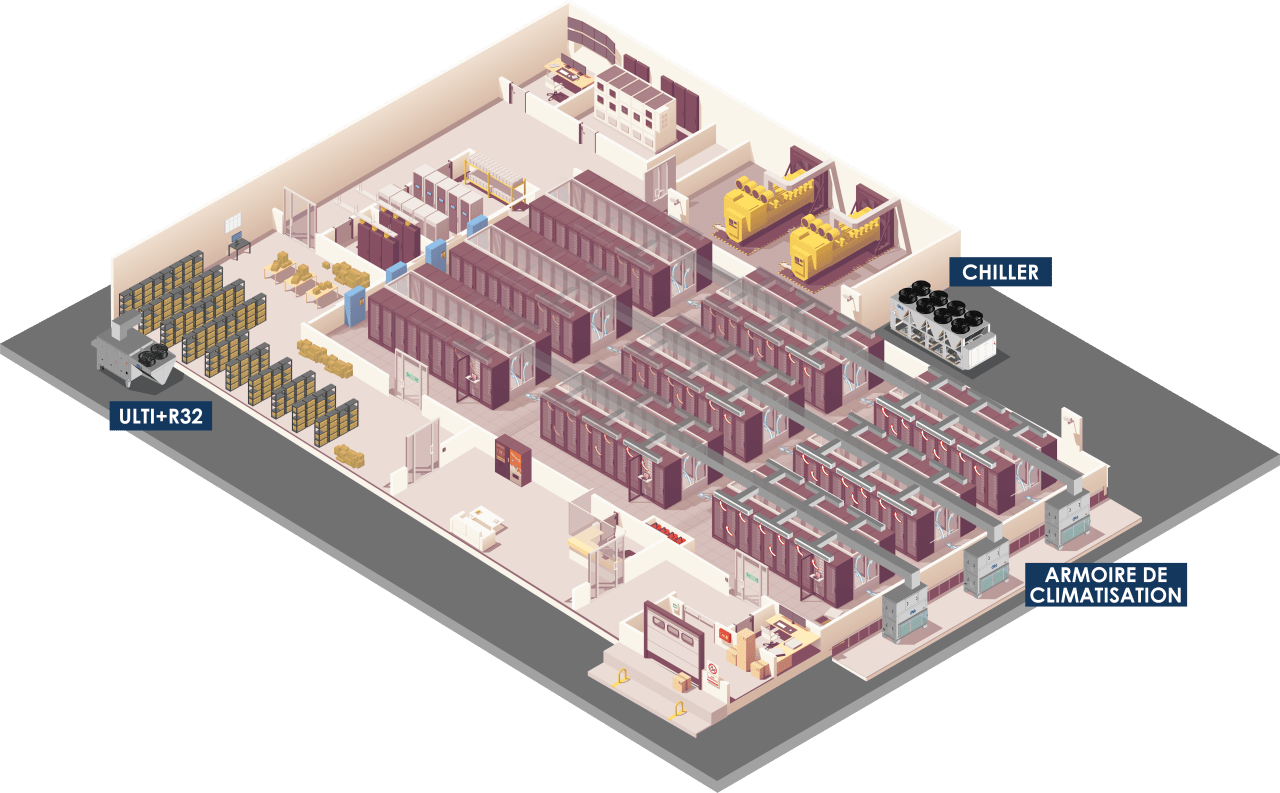

Careful attention will be paid to the design of the air distribution system to avoid hot spots.

Optimum layout of hot and cold aisles is essential to maximise cooling efficiency. The hot aisles concentrate the heat dissipated by the servers, while the cold aisles bring in fresh air.

It is good practice to work with raised floors and false ceilings to facilitate air circulation and cabling, allowing better management of space and cooling.

In addition, to ensure constant availability, data centres incorporate redundant cooling systems (N+1, 2N) to prevent failures and guarantee a stable environment for equipment.

These numerous constraints are critical to the smooth running of data centres, having a direct impact on their energy efficiency and reliability.

In addition to integrated heating and cooling via our thermodynamic system, it's possible to add supplementary equipment such as:

- Condensing gas modules

- Direct or indirect adiabatic coolers

- Chilled water, hot water, steam or CO2 coils

- Electric preheating, heating and auxiliary coils

Many industrial applications require ambient humidity regulation. This involves implementing equipment to dehumidify or humidify the air, such as:

- Thermodynamic or desiccant dehumidification

- Steam humidification with or without integrated production

Energy efficiency is a key concern for manufacturers. To this end, ETT can integrate various equipment and control features such as:

- Thermal wheels, plate heat exchangers, heat pipes, glycol coils

- Free cooling management

Managing air flow is essential for proper industrial process operation:

- Air turnover rate / homogenization of temperature and humidity conditions

- Fresh air compensation (process extraction)

- Positive or negative air pressure management

- High pressure air supply

Numerous constraints often require machines to be designed for integration into their environment. ETT's flexibility allows for:

- Custom dimensions and multi-block design

- Reinforced casing

- Anti-corrosion treatment of components and casing for harsh environments

- Aluminum or STAINLESS STEEL casing, paint finish

- Adaptation to acoustic constraints

Air quality is an important factor for operator comfort and production quality, requiring equipment for:

- Particle and molecular filtration

- Fresh air management

- ATEX (explosive atmosphere) risk management

Recent regulatory developments, particularly the F-Gas regulation, strongly encourage the use of natural refrigerants.

For several years, ETT has been incorporating Propane (R-290) as a refrigerant in various types of machines (air and water-based) such as:

- Air-to- Air heat pumps

- Chillers up to 1.2 MW

- Heat recovery chillers

- High temperature heat pumps up to 70°C

Special attention must be paid to equipment control to meet manufacturers' expectations. This is why ETT develops all of its algorithms to offer customized operation.

Additionally, the myETTvision supervision tool allows manufacturers to monitor their machines remotely and in real-time.

Your project

New build

Refurbishment

In pictures...

Dedicated solutions

Have a question?

A project?

High-performance, sustainable solutions for the data centre sector

The size of the data centre market was €879 million in 2023 and is expected to reach €1.121 billion in 2028 and €1.244 billion in 2033.

France has around 260 commercial data centres, with a forecast of 550 by 2030. In addition, there are around 5,000 private data centres.

The majority of investment (86%) is concentrated in the Paris Region, a key region for the FLAP market (Frankfurt, London, Amsterdam, Paris). Another significant region is the PACA region, mainly Marseille, which attracts around 13% of investments.

These figures show a significant growth dynamic and a favourable environment for the development of data centre infrastructures in France.

Regulations

In France, regulations governing air treatment in data centres aim to ensure optimum energy efficiency while guaranteeing the safety and reliability of the equipment.

- French Energy Code: It imposes strict standards for energy consumption, encouraging the use of efficient cooling systems.

- French 2012 Thermal Regulations (RT 2012) and RE 2020: These regulations aim to improve the energy performance of buildings, including data centres, by imposing limits on primary energy consumption.

- European directive on energy efficiency: Transposed into French law, it encourages rigorous energy management practices.

- Specific standards (ISO/IEC 30134-1) : These define energy performance indicators for data centres, such as Power Usage Effectiveness (PUE).

Finally, good practices such as the use of free-cooling and advanced thermal management systems are encouraged to reduce the carbon footprint of data centres.