Understanding your industry challenges

Because of the processes they use to transform materials, businesses consume large quantities of energy, in the form of electricity, gas or other energy products.

Energy use is therefore a key factor in the competitiveness of the chemicals sector, accounting for between 25% and 35% of total production costs. For the cosmetics and pharmaceutical sectors, energy represents around 10% of the total cost.

It is therefore essential to make efficient use of energy by adopting the most efficient technologies on the market.

ETT is recognised as a specialist in high-performance heat pumps and offers a wide range of technical solutions for:

- Air treatment for specific environments

- Energy recovery

- Hot water and chilled water production

For all hot water and chilled water production units, ETT uses propane (R290) as a natural refrigerant, thereby helping to address the issue of decarbonisation.

In addition to integrated heating and cooling via our thermodynamic system, it's possible to add supplementary equipment such as:

- Condensing gas modules

- Direct or indirect adiabatic coolers

- Chilled water, hot water, steam or CO2 coils

- Electric preheating, heating and auxiliary coils

Many industrial applications require ambient humidity regulation. This involves implementing equipment to dehumidify or humidify the air, such as:

- Thermodynamic or desiccant dehumidification

- Steam humidification with or without integrated production

Energy efficiency is a key concern for manufacturers. To this end, ETT can integrate various equipment and control features such as:

- Thermal wheels, plate heat exchangers, heat pipes, glycol coils

- Free cooling management

Managing air flow is essential for proper industrial process operation:

- Air turnover rate / homogenization of temperature and humidity conditions

- Fresh air compensation (process extraction)

- Positive or negative air pressure management

- High pressure air supply

Numerous constraints often require machines to be designed for integration into their environment. ETT's flexibility allows for:

- Custom dimensions and multi-block design

- Reinforced casing

- Anti-corrosion treatment of components and casing for harsh environments

- Aluminum or STAINLESS STEEL casing, paint finish

- Adaptation to acoustic constraints

Air quality is an important factor for operator comfort and production quality, requiring equipment for:

- Particle and molecular filtration

- Fresh air management

- ATEX (explosive atmosphere) risk management

Recent regulatory developments, particularly the F-Gas regulation, strongly encourage the use of natural refrigerants.

For several years, ETT has been incorporating Propane (R-290) as a refrigerant in various types of machines (air and water-based) such as:

- Air-to- Air heat pumps

- Chillers up to 1.2 MW

- Heat recovery chillers

- High temperature heat pumps up to 70°C

Special attention must be paid to equipment control to meet manufacturers' expectations. This is why ETT develops all of its algorithms to offer customized operation.

Additionally, the myETTvision supervision tool allows manufacturers to monitor their machines remotely and in real-time.

Your project

New build

Refurbishment

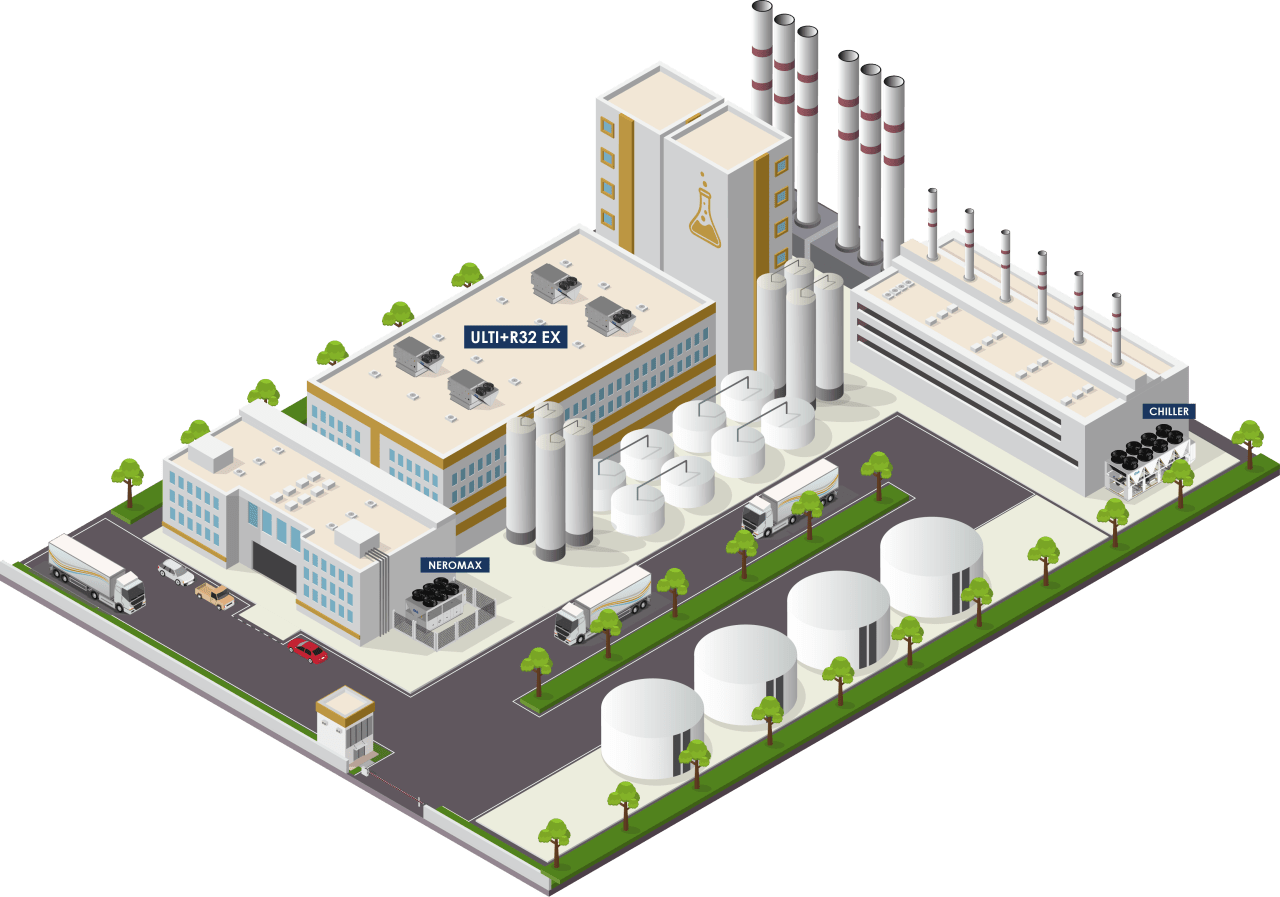

In pictures

Dedicated solutions

Have a question?

A project?

High-performance, sustainable solutions for the cosmetics, chemicals and pharmaceuticals sectors

The chemical, cosmetics and pharmaceutical industry in France is a key sector of the economy, making a significant contribution to production, employment and innovation.

The chemical, cosmetics and pharmaceutical industries generate total sales of around 187 billion euros.

These industries directly employ around 570,000 people.

5% of sales reinvested each year in research and development.

These figures show the importance of these sectors not only for the French economy, but also for innovation and France's international competitiveness.

Regulations

Regulations governing air treatment in cosmetics, chemical and pharmaceutical plants are rigorous, and aim to guarantee product safety, worker health and environmental protection.

- Health and safety standards: Factories must comply with Good Manufacturing Practice (GMP) standards, specified by the French National Agency for the Safety of Medicines and Health Products (ANSM) for the pharmaceutical and cosmetics industries. These standards include strict air quality requirements to prevent product contamination. Ventilation and filtration systems must maintain appropriate air quality, particularly in terms of particles, microbes and chemical substances.

- Environmental regulations: The Environment Code requires plants to control emissions of atmospheric pollutants. - Air treatment systems such as particle filters, gas scrubbers and solvent recovery devices are often required.

- Industry-specific stand:

Pharmaceutical industry: Facilities must comply with European Union directives, in particular EU GMP (EudraLex Volume 4). The classification of areas according to their level of cleanliness (class A to D) dictates the specifications for air treatment, including the number of air changes per hour and the types of filters to be used (e.g. HEPA).

Cosmetics industry: ISO 22716 provides guidelines for good manufacturing practice, including requirements for ventilation and air quality in production areas.

Chemical industry: REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) regulations impose strict controls on the chemicals used and emitted, requiring appropriate air handling systems to limit the risks of exposure.