Understanding your industry challenges

The goals for reducing consumption align with short- and medium-term decarbonization aspirations. ETT supports leaders in the industrial laundry sector by designing and manufacturing high-performance, innovative equipment.

Our expertise focuses on the production of hot water and laundry drying, offering fully decarbonized solutions. These two areas are highly energy-intensive, and our thermodynamics-based solutions combine energy savings, decarbonization, and productivity.

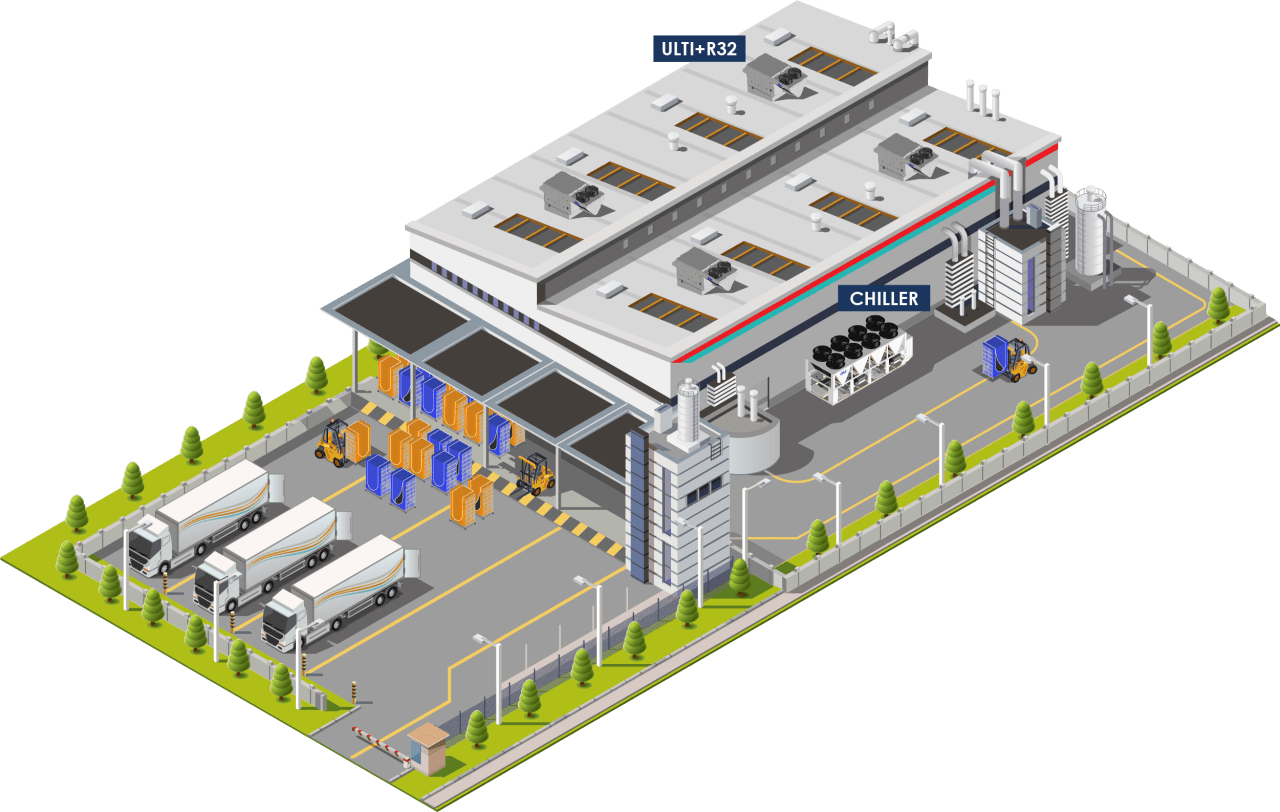

We also engage in air treatment to provide thermal comfort for operators. The waste heat can be repurposed to assist in the hot water production needed for washing cycles.

ETT's solutions for meeting the aeraulic and economic challenges of laundries incorporate a range of functions.

This ETT innovation, combined with a heat pump, meets the need to reduce consumption while maintaining summer comfort.

The control system adapts the machine's operation in real time to optimise energy consumption.

The ULTI+ R32 OR range can be installed on a water loop. This system combines performance (SEER / SCOP, no defrosting, wide operating range) and accessibility (installation on standard upstand, installation in equipment room possible). Three hydraulic configurations are available.

Dehumidification in sales areas is essential for maintaining a comfortable and healthy indoor environment. By regulating humidity levels, it helps prevent the formation of condensation, which can damage products and materials, while ensuring the well-being of customers and staff.

Your project

New build

Refurbishment

In pictures...

Dedicated solutions

Have a question?

A project?

Innovative Solutions for Laundries : Performance and Ecology at the Heart of our Systems

The laundry industry in France generates an annual revenue of approximately 3 to 4 billion euros.

The market has shown steady growth in recent years, with variations depending on the served sectors and technological innovations.

Approximately 1,500 to 2,000 companies operate in the industrial laundry sector in France, including both large enterprises and SMEs.

The sector employs around 30,000 to 35,000 people in France.

Regulations

Regulations concerning air treatment in industrial laundries are stringent to ensure worker safety and environmental protection. The French labor code mandates specific standards for ventilation and aeration to ensure optimal air quality. Industrial laundries must install effective ventilation systems to evacuate pollutants, including chemical vapours and dust.

Installations must comply with standards set by the INRS (French National Institute for Research and Safety), detailing requirements for pollutant capture at the source, filtration, and air renewal. Additionally, facilities classified for environmental protection (ICPE) must adhere to prefectural orders and European regulations regarding atmospheric emissions and solvent management. These measures aim to minimize health and environmental risks associated with laundry operations.