Understanding your industry challenges

The hospital sector includes a wide range of environments, each with distinct constraints based on the type of facility (patient accommodation, central pharmacy, laundry services, care homes, etc.). ETT provides reliable air conditioning, ventilation, and heating systems that address various technical and regulatory challenges while ensuring the comfort of medical staff and patients.

Air quality:

The hygienic renewal of fresh air is a crucial issue for maintaining optimal hygiene and comfort conditions for both patients and medical personnel, especially in accommodation and treatment areas.

ETT has developed solutions to help you manage this fresh air intake through effective, high-efficiency systems, particularly with the X-RCAM+ range.

Chilled and hot water production:

Whether constructing a new care home, expanding a hospital building, or replacing an existing production system for a central kitchen, the current environmental challenges facing the healthcare sector encourage you to prioritize energy recovery and integrate a comprehensive decarbonisation approach.

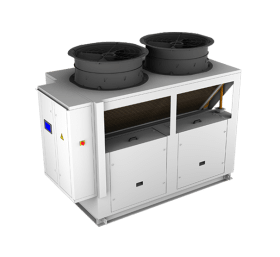

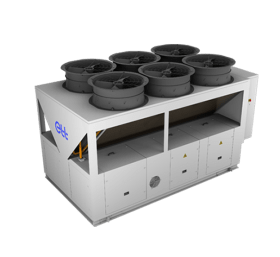

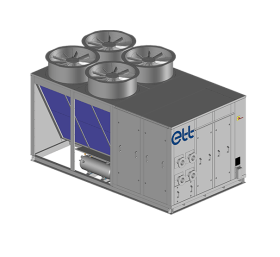

To this end, ETT offers high-efficiency chilled and/or hot water production solutions, such as the NEROMAX and ECOPS ranges, which run with natural refrigerant R290.

Temperature and Humidity Control:

Some hospital sites are equipped with central pharmacies, laundries or even a rehabilitation centre with indoor pools. In all these cases, temperature and humidity control is essential to ensure the comfort of patients and healthcare staff, the storage of certain products (vaccines, medicines, etc.) and even the removal of moisture to preserve the building.

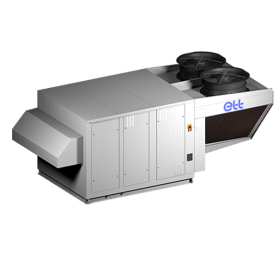

To meet these requirements, ETT has developed innovative systems for humidity and temperature control with high-performance coefficients and tailored regulation, such as the modular rooftop systems ULTI+ R32/R290 DESHU and the X-POOL+ double-flow dehumidifier.

ETT Solutions that address airflow and economic challenges incorporate various functions:

Maintaining air quality in the healthcare sector is essential for ensuring hygiene and comfort for both patients and staff.

To achieve this, ETT incorporates specific filtration and control systems that enable optimised conditioning of hygienic fresh air.

Energy efficiency is a central concern in contemporary environmental considerations. With this objective in mind, ETT is able to integrate various equipment and features such as plate heat exchangers and glycol water coils.

The latest regulatory developments, particularly F-GAS, strongly encourage the use of natural fluids.

For several years now, ETT has been integrating propane (R-290) as a refrigerant in various machine types of machines (air- and water-based).

Special attention must be paid to equipment control to the regulation of equipment to meet the expectations of healthcare facilities. This is why ETT develops all of its algorithms to offer personalised operation.

Additionally, the myETTvision monitoring tool allows operators to track their machines remotely and in real-time.

Dimensional constraints often lead to challenges in integrating new equipment when replacing existing systems.

ETT's strength lies in its ability to offer completely customised machines that fit in with their environment.

Your project ?

Renovation

Dedicated solutions

Have a question ?

A project ?

Reliable and efficient solutions for the medical and medico-social sectors

For over 45 years, ETT has been putting at the service of its customers to best meet their needs.

More than 350 ETT machines have been installed in healthcare facilities, including:

Regulations

The healthcare sector is subject to numerous standards and regulations that must be considered in project design and technical decision-making.

Healthcare establishments are subject to strict requirements regarding Indoor Air Quality (IAQ), aimed at ensuring a healthy environment for the patients and medical staff. Monitoring IAQ is now a public health imperative, with specific legal requirements for establishments open to the public.

- ISO 14644: This is an international standard from which NF S 90-351 is derived, defining the different classes of air cleanliness in clean rooms. These classes determine the target values to be achieved in terms of particle size and concentration in the treated air.

- EN 1886: This European standard defines requirements and classifications of air handling units in terms of mechanical deformation, thermal performance, and airtightness. This governs the design and manufacturing methods for our equipment. ETT units tested are classified as D2/L1/F9/T2/Tb2.